What if your manufacturing company could keep the machinery running properly, well-maintained, and secure — and all this without providing an actual site inspection? Or what if you could develop multiple product iterations to check which design and materials would suit you better without building the product and spending real-life resources?

Both are the promise of digital twins, a new tool in manufacturers’ arsenal that’s disrupting the industry by connecting the physical and digital worlds and allowing companies to create a virtual replica of their physical environment — processes, products, and facilities. So they transform into a digital twin company.

This article dives deep into the technology of digital twins in the manufacturing industry. Aside from learning about what the technology is in general, you can read about its major use cases and digital twins examples in manufacturing.

Digital Twin in Manufacturing: The New Trend

In December 2021, ABI Research analysts published a report titled “70 Technology Trends That Will and Will Not Shape 2022”, which covered 35 trends that are expected to dominate the market in the upcoming year and 35 trends that wouldn’t be nearly as popular as industry leaders predicted earlier. Among these, machine learning in manufacturing is highlighted as a key trend driving innovation in the industry.

The report proved digital twin technology as one of those trends that are getting popular in global manufacturing. Global spending on industrial digital twins is projected to reach $4.6 billion in 2022 and $33.9 billion in 2030 at a 28% Compound Annual Growth Rate (CAGR).

It’s interesting that the concept of digital twins was introduced as early as in 2001. But it was rejected soon because of the complexity and the inability of businesses to handle the information needed to get real value from this technology.

So, what are digital twins?

In plain language, a digital twin refers to an exact virtual copy (or twin) of a real-world asset. It could be a digital mirror of the machine, equipment component, or process — almost anything in manufacturing that has networked sensors and can send information to and from the virtual model. Thanks to IoT, manufacturers can get a clear picture of the equipment’s condition and its history.

Here’s a simple example. A food manufacturer has a critical component in its production line. This component uses IoT devices to send updates about how quickly and efficiently it’s processing raw materials back to a digital twin. In this scenario, machine operators don’t need to investigate the physical equipment part to make conclusions about how it’s performing — it’s enough to look at its digital twin.

What’s there for manufacturers?

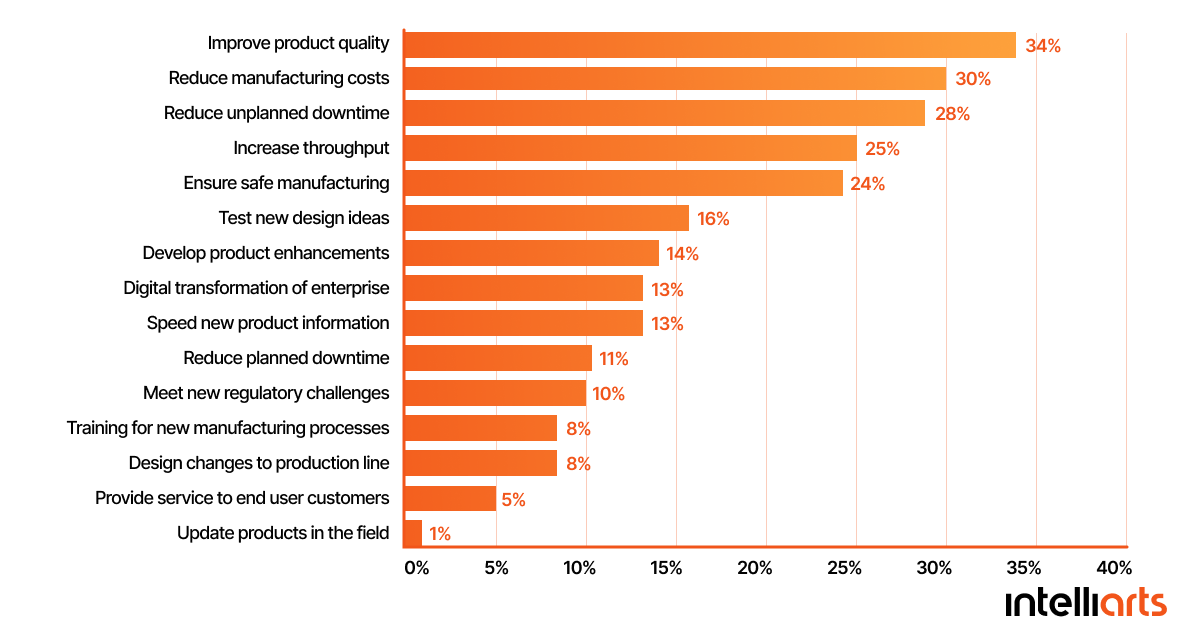

There are actually many drivers of digital twins in manufacturing, and we mention them below. The point is that manufacturers are getting more enthusiastic about digital twins. Here is what the survey of 300 manufacturers from a wide range of industries, from semiconductor to oil and gas, has revealed about the use of a digital twin in the manufacturing process:

So why exactly manufacturers are opting for digital twins today? We list four reasons:

-

Production flexibility delivered by digital twins is truly valuable in the context of mass customization and individualized demand. The technology allows to experiment with lots of product variants as well as to react to market changes faster and reschedule production if needed.

-

The popularity of digital twins is also connected to the manufacturing skill gap currently present in the industry. Despite reductions in available labor, businesses can keep production at the same level and test different production setups to find the most suitable options. One machine operator can be responsible for several apparatuses as a digital twin analyzes the impact of different inputs and processes on productivity.

-

Digital twins contribute a lot to the competitive edge of a manufacturing company, which is especially valuable in an ever-increasing level of business competition. If a digital twin is combined with machine learning (ML) technology, it can help the company predict equipment failure better and, thus, improve product quality and cut maintenance costs. Add here reduced costs related to testing products, the increase in productivity, and lower process variability — and a manufacturing company would stay ahead of most of its competitors.

-

Last but not least, the technology is largely associated with internal process improvement initiatives. For example, a digital twin can make production more transparent for stakeholders. It can also improve employee safety by detecting potential hazards on a factory floor.

Manufacturers from the mentioned LNS survey named specifically how digital twins were useful to them:

Top digital twin use cases in manufacturing

Now let’s move to the applications in the manufacturing for the digital twin industry:

1. Process optimization

A manufacturer can use sensors in a production line to create digital twins of its processes and monitor the most important performance indicators. Based on the collected data, the company can model what is normal and, with the help of a digital twin, track the variations from this model in real time.

This data-driven model could also help businesses conduct root-cause analysis and identify gaps in manufacturing processes that lead to the waste of resources. Eventually, manufacturers will come up with more ideas of how to optimize production, reduce expenses and waste.

2. Fault prediction

Combine digital twins with machine learning (we’ll talk about it in a minute), and you can analyze data collected by digital twins to predict breakdowns and take action before the problem even occurs. For instance, a digital twin powered by ML can help manufacturers visualize a racecar engine so the company can predict the required maintenance, such as which part is about to burn out. Besides, you can order new parts in advance to avoid the risk of downtime and cut maintenance costs.

The manufacturer should remember, though, the importance of collecting quality data. Sometimes, companies find it difficult to access enough quality data required to train the fault prediction model, especially if it comes to complex equipment. Consultancy of machine learning experts could be of great advantage here.

3. Quality management

Digital twins can also be useful in improving manufacturer’s quality indicators. By modeling the entire production process with a digital twin, the company can detect where variances occur and/or know if better materials can improve the situation. As a result, the manufacturer would get a better chance to be in line with today’s requirements of high-tech production and make timely improvements to its product and the production process generally. The company can also cut its expenses since it has to redo products more rarely if its production is under the guidance of the digital twin.

4. Streamlined prototyping process

Another use case of digital twins on a factory floor includes product development and design customization. Here digital twins can help manufacturers compare how different products or designs will perform in real-life circumstances. Businesses can test as many iterations as needed experimenting with physical attributes, numbers of parts, properties, and materials. By doing this, they would not waste company resources while reducing time to market.

Machine construction in manufacturing requires lots of costs, so digital twins can come in handy here too. In this scenario, the manufacturer loads data from the real machine into the digital model and simulates and tests ideas before putting them into manufacturing.

5. Optimized supply chain

Applying digital twin technology in supply chain management is also beneficial. Plant managers get a better understanding of how materials are used and can automate the process of replenishment. The technology can improve packaging performance and the chosen route efficiency. Additionally, the integration of IoT in the supply chain further enhances real-time monitoring and decision-making capabilities. Altogether, this can cause significant improvements in inefficiency.

Empower digital twins with machine learning

As we’ve partly covered, digital twins perfectly combine with ML. Although analytics code could be written with the use of programming languages or a simplified rules engine, incorporating ML algorithms contributes a lot to the manufacturer’s opportunities and efficiency of the system.

An expert team of data scientists trains an ML model so it can differentiate abnormal behavior patterns in the production line. The model is trained, tested, and fine-tuned to be deployed to a digital twin so the system can track equipment performance and alert when it notices suspicious activity.

For example, consider manufacturing equipment that periodically measures three parameters (temperature, pressure, and vibration) and supplies this data to the digital twin in real time. An ML model then monitors the data for anomaly detection. The manufacturing company gets alerts if any:

How does ML and AI optimize the use of digital twin tools in manufacturing?

- The technology can help manufacturers solve more complex tasks thanks to the use of machine learning for predictive maintenance for predictive maintenance and allows working with complex datasets.

-

It can increase the number of possible data types (images, texts, and so on)

-

The integration of ML and AI enables manufacturers to solve problems faster and more efficiently. For example, thousands of data sets can get analyzed automatically and fast with scalable performance

Best digital twin manufacturing examples

Unilever PLC

The British consumer goods giant, Unilever PLC, has built digital copies of its factories in different parts of the globe, aiming to make its production more efficient and flexible. On the factory floor at each location, IoT sensors collect real-time performance data such as pressure, humidity, or temperature and send them to the cloud.

After that, by using advanced analytics and machine learning algorithms, digital twin technology helps to simulate complex what-if scenarios and delivers insights about the best operational conditions to Unilever. The manufacturer applies these insights to use its materials better, limit waste from products, and improve quality.

Vajda Papír

A Hungarian paper manufacturer, Vajda Papír, had a chance to appreciate its digital transformation during the Covid-19 pandemic. As more people were staying at home, the company met the growing demand for napkins, toilet paper, and paper towels and was forced to produce more.

The manufacturer coped with this increasing pressure on its production line with the help of IoT and predictive maintenance. This technology helped the company control the manufacturing process and extend the useful life of machines. A digital twin of its processes also gave it a great competitive advantage. Thanks to the digital twin, Vajda Papír could guide its production operators effectively through maintenance and repairs, as well as ensure data transparency to stakeholders.

General Electric

The multinational conglomerate company, General Electric (GE), is known for the use of digital twinning and machine learning in building and maintaining its wind power plants. GE’s virtual models help engineers monitor and control turbines and increase the productivity of its heavy machinery.

For one thing, the technology allows the company to detect any maintenance issues before they even occur. For another, digital twins are useful in predicting power output. Based on the collected data, the company copes with the unpredictability of weather conditions and makes prognoses about the average amount of energy generated per month.

Read also: Predictive Maintenance in Manufacturing: Benefits, Trends and Examples

Electroimpact

The UK aerospace company Electroimpact is working on a trial project in wing construction. The manufacturer has introduced digital twinning to its manufacturing process to improve quality and reduce time-to-market.

At first glance, aircraft manufacturing seems one of the most innovative industries, though some processes are still old-fashioned and done manually there. In wing production, manufacturers usually encounter a problem when holes don’t align exactly where they should be. The operators have to do last-minute adjustments on the production line, which results in production delays.

Electroimpact believes digital twins can easily solve this problem — the manufacturer could build the corresponding parts so they fit the whole product seamlessly.

GlaxoSmithKline

GlaxoSmithKline (GSK) is the UK’s largest pharmaceutical company, which stands out with its innovative approach to pharma manufacturing. For example, the company has introduced in-line sensors to track its entire production process in real-time at every step.

The digital twin of the pharmaceutical process helps the manufacturer improve its operation and simulate changes to get insights for development and full control over its production. In the long run, it allows to speed up time to market, improve quality standards, and lower costs through reduced waste.

Where to next?

Visit a smart factory, and you’ll see how digital twin technology is making its debut there. There is so much equipment, IoT devices, and intelligent systems, all running endlessly and collecting data at every little step of the manufacturing process. This data should be processed and analyzed, so the manufacturer could leverage its power.

Following this logic, digital twins in manufacturing arose not as a whim but out of necessity. Together with machine learning, this technology allows optimizing operations on a factory floor, improving product quality, and reducing time to market. Both technologies place insights into how to increase efficiency directly into the hands of your manufacturing operations. Don’t forget to grasp this opportunity.

In case you’re wondering how machine learning can optimize your production processes, request a consultation. Intelliarts has wide expertise in manufacturing software development services, and we’ll be glad to cover all your questions.