How to leverage all the data collected by sensors? How to get insights from it? Will they help draw data-driven business decisions? One of the ways to get answers to these questions is to apply data analysis. This article will explain why IoT systems need data analytics in the automotive industry for proper operation and how critical decisions can be made based on this analysis.

IoT analytics is the application of data analysis tools and procedures to realize value from the huge volumes of data generated by connected Internet of Things devices. It is an innovative and challenging area. Sensor, mobile, and wireless technologies drive its evolution, but the actual value of the IoT lies in big data analytics rather than hardware modernities. Being software developers pioneering IoT analytics, we will explain how IoT data analytics in the automobile industry enhances transformative business opportunities.

Primarily due to data analytics the automotive industry has evolved rapidly over the past decade. Using automotive data analytics helps the sector grow in many ways by improving safety, reducing repair costs, extending uptime, and much more. It brings a ton of unique opportunities for experts in the field, helps to decide where to invest funds, recognize growth opportunities, predict incomes, and handle unusual situations before they convert into problems.

Data analysis types

There are many types of IoT data analysis in the automotive industry. Below you can find their main types:

-

Descriptive analysis

-

Exploratory analysis

-

Diagnostic Analysis

-

Predictive Analysis

-

Prescriptive Analysis

Now let’s take a look at each technology and what benefits it brings.

Descriptive analysis

This method is the opening point to any analytic process, as it intends to explain what happened. Its tools are ordering, manipulating, and extracting raw data from multiple sources in order to turn it into valuable insights for the business. Descriptive analysis in the automotive industry can provide companies with insights into sales performance, market trends, and customer preferences.

Conducting descriptive analysis is crucial because it enables us to display our data in a meaningful way. In the long run, it helps automotive companies to make informed decisions, optimize processes, and identify areas for improvement.

Using this method solely will not let you predict future results or answer questions like why something happened. It can still organize your data, so it’s ready for further analytics.

Power your growth with expert big data consulting — from strategy to execution.

Exploratory analysis

Data professionals use exploratory analysis to investigate data sets and compile their main characteristics, often employing data visualization methods, enabling them to find connections and generate hypotheses and solutions for specific problems. In the automotive industry, exploratory analysis helps to dive deeper into factors influencing vehicle sales, market dynamics, etc.

In addition, exploratory analysis helps determine how to handle data sources to acquire the insights you need, making it easier to discover patterns, spot anomalies, or test theories. This way, automotive companies identify potential opportunities and challenges for strategic decision-making in the sector. Summary statistics and graphical representations are the most helpful means in this case.

Diagnostic analysis

This one is about the reason something happened and answers the “Why?” question by determining the cause of events. This type of analysis in the automotive sector helps to identify performance patterns, root causes of production inefficiencies, quality issues, or supply chain disruptions.

If you know why something happened and how it happened, you will be able to pinpoint the exact ways of tackling the issue like improving the overall operational efficiency or product quality.

Predictive analysis

Predictive analysis in the automotive industry tells you “what may happen”. It makes predictions based on current or past data. For example, this approach can help automotive companies predict maintenance needs, optimize supply chains, and anticipate market demand for specific vehicle models or features.

We need to bear in mind that forecasting is only an estimate, whose accuracy is based on the amount of detailed information you have and how correctly you use it.

Prescriptive analysis

Prescriptive analysis consolidates the insight from all previous analyses and decides what is best to be done. In the automotive sector, it can suggest strategies for inventory management, production planning, and supply chain optimization in IoT. This approach helps automotive companies to understand what might happen as well as to determine the best actions to achieve desired outcomes.

Most data-driven automotive businesses use descriptive and predictive analytics but these are usually not enough to improve performance. So they analyze the data and make decisions based on current situations and problems.

Benefits of data analysis in the automotive industry

Automotive is presumably one of the top industries that experience the benefits data analysis provides to the fullest. Data analysis use cases in the automotive industry are numerous, and all of them launch a wholesome new niche inside the market. Let’s review some of the key applications of IoT in the automotive industry below:

1. Better customer experience

Carmakers have been using data analysis for quite a long time. They design and develop custom solutions to improve clients’ experience. With the help of data analysis and IoT data analytics in the automotive industry, we can make vehicles safer, enhance driving experiences, and increase the level of service. The data may be collected from different sources simultaneously: from the car, its driver, the surroundings, and, of course, from special devices.

2. Connected cars

Connected cars are getting even more connected and automated thanks to IoT. Data analysis enables car manufacturers to monitor engines and manage powertrain performance.

3. Vehicle fleet management

Data analysis can help with preventing speeding and aggressive driving by collecting big data from the sensors and interpreting it according to the pre-set requirements. Such technology may help keep cars’ peak performance and minimize endangered vehicle usage.

4. Timely car maintenance

For the mass market, vehicle data analytics for automotive dealerships is just as beneficial. After predicting the possible issues car manufacturers may notify drivers about car maintenance needs and so prevent unexpected breakdowns. In the long run, this helps to save maintenance costs and extend the product lifespan.

5. Driver behavior prediction

Predictive data analysis can be advantageous for insurance businesses as well, as it allows companies to predict the behavior of the driver and monitor the driver’s safety. It might also be beneficial in case of an accident, as the data collected from a vehicle is reliable and accurate. This helps to reduce the number of false claims, which benefits insurance companies and legal authorities.

6. Traffic flow improvements

Data analysis and big data analytics in the automotive industry help to improve traffic flows. They help to define the best place to build rest areas and understand where to locate the traffic lights or pedestrian crossing. Improved alarm systems can alert people about weather conditions, construction works, or sharp turns, which all serve human safety and comfort. IoT in smart grid technology also plays a significant role in enhancing these systems by enabling real-time data collection and analysis for more efficient traffic management.

IOT data analytics in automotive industry use-cases

It’s always easier to grasp the full power of technology when you see a real case with actual companies, data, and results. So here are several success stories of data analysis making industrial magic happen.

Data analysis on rails

Let’s take Siemens as an example. Having more than 150 years of experience in train engineering, the company connected its innovations to vehicle data analytics. It now uses sensors to analyze information on trains and tracks, which helps to move railway maintenance methods from reactive to predictive. Siemens can detect patterns that indicate when a breakdown is likely to happen by assessing the condition of components through diagnostic sensor data. As it’s possible to monitor information in near real-time, the producer can promptly react to concerns before they disrupt the system. When anomaly is detected, it just sends the part for inspection.

The benefits of this approach are:

- A reduction in delays

- Increased mileage

- Lower labor costs

- More efficient maintenance scheduling

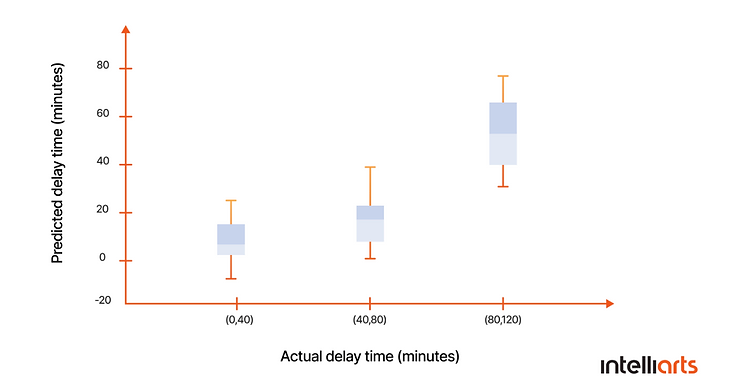

Data analysis can also be used to explore the patterns of train delays and make long-term delay predictions. Pu Wang and Qing-peng Zhang, Chinese scientists, are the ones who developed an ML model for such predictions. They collected multi-source big data sets, which included train schedules and delays and weather data, and analyzed the impact of various factors on train delay time. As a result, they built the model to predict the trend of train delays, which helps railway operators improve their train management plans.

Data-driven cars

Automakers, drivers, and citizens benefit from vehicle data analysis as well. Modern cars can contain more than 50 sensors that collect data on speed, fuel consumption, emissions, and security. We can use all this data to instantly detect patterns, resolve quality issues, and prevent them from happening. Analytics is used to improve customer satisfaction and quality management quickly and cheaply.

Car recall used to be a common menace in the industry. Today Predictive Analysis is actively applied to decrease the risks of recalls. Modern manufacturers use predictive analytics in automotive to collaborate with the government so that they can identify and predict high-congestion zones using data from automobiles for urban planning and building. By combining insights from automotive data and other sources such as GPS, satellites, cellphones, etc we can deal with urban issues like traffic management, distribution of resources, and environmental problems.

Auto manufacturers now offer round-the-clock connectivity and digital experience across all engagement channels. For instance, Audi cooperated with Adobe to provide visitors of their website with a completely new brand experience: news, links to dealers, and vehicle guides. An interactive application called Audi Configurator enables their customers to design tailored cars. The role of the dealer is now to use opportunities and transform the existing retail experience on offer.

Conclusion

Major sectors of the automotive business are growing and getting smarter every month. Gathering data isn’t enough now, as the global market makes the competition stronger than ever. Thus, the importance of data analysis in business is evident for every company aiming for the future. Aside from offering low-cost computation, storage, and operational capacities, IoT data analytics in the automobile industry can save a lot of time and, as a result, costs.

If you are considering investing in IoT data analytics in the automotive industry, now is a great time to get on the bandwagon since there is so much you can achieve with IoT analytics.

We at Intelliarts love to help companies solve challenges through data strategy design and implementation. If you have any questions related to ML pipelines in particular or other areas of data science consulting services — feel free to reach out and get our experts’ consultation.

FAQ

1. How is IoT used in the automotive industry?

In the automotive industry, IoT is leveraged for telematics, connected car services, predictive maintenance, and safety measures. Its benefits include vehicle capability enhancement, optimized operations, and improved driving experiences.

2. What are the IIOT applications in the automotive industry?

Industrial Internet of Things (IIoT) applications in automotive include real-time monitoring and optimization of manufacturing processes, predictive maintenance for machinery, and data-driven supply chain management to enhance efficiency.

3. How big is the automotive IoT market?

According to the Worldwide Research report, the global automotive IoT market was valued at approximately $40 million in 2020 and is expected to reach $101 million by 2028. This success is usually attributed to the expansion of connected cars, smart manufacturing processes, and other IoT applications in automotive.