The study by PwC indicated that, 46% of companies have fully adopted IoT in their supply chains, second only to cloud-based platforms. That basically means that soon enough, the magnitude of companies resisting such a transformation will start falling off.

Moreover, projections indicate that by 2033, the IoT in supply chain management market will reach $41.8 billion, with a compound annual growth rate (CAGR) of 12.9% from 2023 to 2033. It clearly shows the high rate of adoption of IoT green supply chain technology.

In this post, you’ll explore challenges with implementing green supply chains with IoT technology as well as the role of IoT in business. Besides, you’ll find out what AI in green chains issues are there and how to solve them. Moreover, the post offers AI and IoT in supply chain implementation strategies and real-life cases.

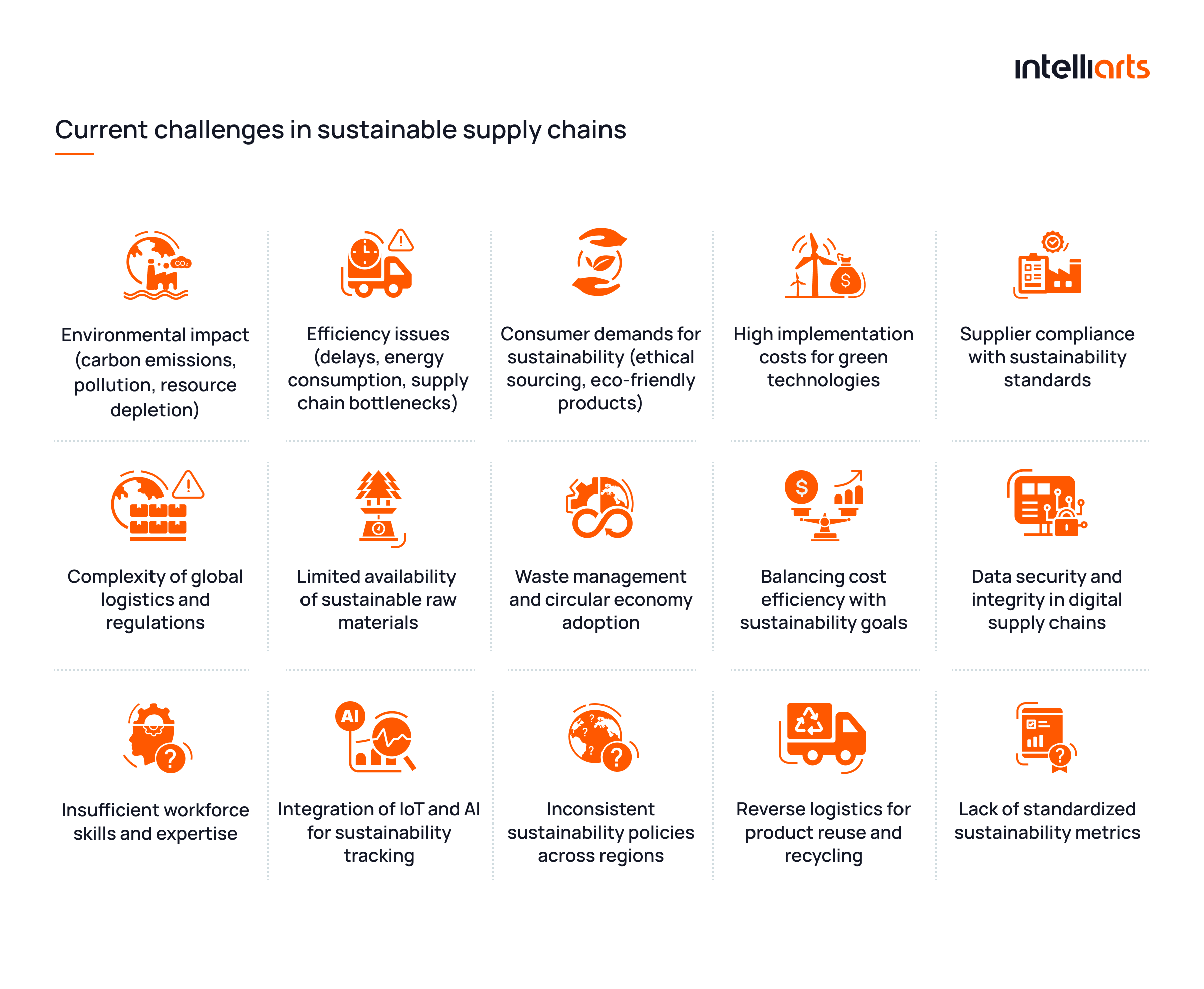

Current challenges in sustainable supply chains

Let’s begin by reviewing an IoT green supply chain issues that still complicate digital transformation for businesses in the niche:

Using IoT in smart grid is one of ways to address energy and sustainability challenges. Explore more in another of our blog posts.

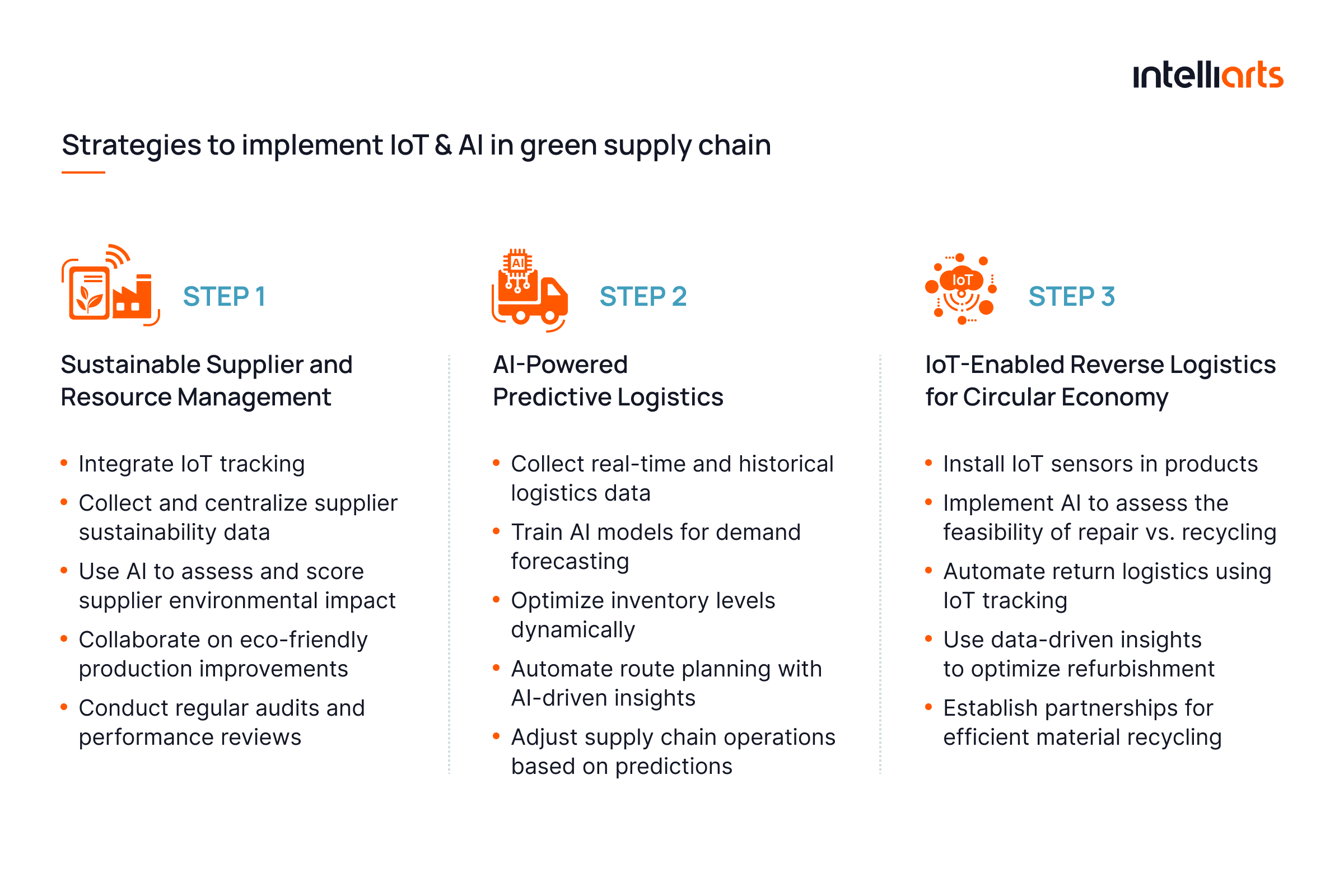

Implementing IoT & AI in green supply chain strategies

We are already aware of both sustainable supply chains and AI implementation in green chains issues. This brings us to the necessity to delve into strategies to build an IoT green supply chain with IoT and AI:

#1 Sustainable Supplier and Resource Management

The strategy lies in using IoT to monitor supplier sustainability practices and AI to analyze compliance with environmental standards.

Implementation steps:

- Integrate IoT tracking for supplier emissions and resource use

- Collect and centralize supplier sustainability data

- Use AI to assess and score supplier environmental impact

- Collaborate on eco-friendly production improvements

- Conduct regular audits and performance reviews

Expected impact: Greater supply chain transparency, eco-friendly sourcing, and stronger sustainability compliance.

Who benefits: Automotive companies, Fashion and apparel brands, Food and beverage companies.

Explore additionally what green supply management is in the video below:

#2 AI-powered predictive logistics

The strategy involves using AI and IoT to forecast demand, optimize inventory, and enhance transportation efficiency, reducing waste and emissions.

Implementation steps:

- Collect real-time and historical logistics data

- Train AI models for demand forecasting

- Optimize inventory levels dynamically

- Automate route planning with AI-driven insights

- Adjust supply chain operations based on predictions

Expected impact: Lower logistics costs, reduced overproduction, and minimized fuel consumption.

Who benefits: E-commerce companies, FMCG companies, Logistics and delivery services.

#3 IoT-enabled reverse logistics for circular economy

The strategy focuses on using IoT to track product returns, repairs, refurbishments, and recycling efforts to promote a circular economy and reduce waste.

Implementation steps:

- Install IoT sensors in products to track usage and lifespan

- Implement AI to assess the feasibility of repair vs. recycling

- Automate return logistics using IoT tracking

- Use data-driven insights to optimize refurbishment processes

- Establish partnerships for efficient material recycling

Expected impact: Extended product lifespan, reduced waste, and cost savings from refurbished or recycled materials.

Who benefits: Electronics manufacturers, Automotive companies, Consumer goods brands.

Exploring the role of IoT in sustainable supply chains

One of the possible answers to the challenges mentioned above is IoT and AI-driven software. That’s why knowing how IoT enhances green supply chains can prove valuable knowledge for any decision-maker. Here are these roles described in detail:

#1 Carbon footprint monitoring

Implementing IoT in sustainable supply chain strategies enables businesses to track emissions across logistics and production. Smart sensors collect real-time data on fuel consumption, energy use, and waste generation, helping companies optimize processes and reduce carbon output.

Key IoT-driven footprint monitoring features here include:

- Real-time CO₂ emission tracking in vehicles.

- Energy consumption analytics and identification of energy-intensive operations.

- Waste reduction insights.

For additional insights, explore our other article on AI in renewable energy.

#2 Circular Economy Enablement

The green supply chain with IoT promotes circular economy practices by enabling better tracking, reuse, and recycling of materials. Smart IoT-powered monitoring systems improve resource efficiency and waste management.

IoT-enabled circular economy solutions include:

- Material lifecycle tracking to monitor product condition and enable reuse.

- Automated refurbishing alerts for proactive maintenance and repair.

- Smart waste separation using IoT-driven sorting technologies for better recycling.

#3 Smart Packaging Optimization

Optimizing packaging with IoT supply chain sustainability solutions reduces material waste while ensuring product protection. IoT sensors embedded in packaging help maintain product quality and minimize excess materials.

IoT-powered packaging improvements include:

- Temperature and humidity monitoring to ensure perishable goods remain intact.

- Shock and impact detection to prevent damage and reduce unnecessary waste.

- Lightweight, reusable, and biodegradable packaging insights for eco-friendly logistics.

#4 Demand-Driven Production Optimization

With IoT in green supply chain management, businesses can move from overproduction to demand-driven models, aligning production with real-time market demand.

IoT-driven production efficiency includes:

- Automated demand forecasting using real-time sensor data and analytics.

- Dynamic production scheduling to prevent excess inventory and resource waste.

- Operational efficiency tracking to minimize production downtime and reduce emissions.

#5 Sustainable Supplier Management

Ensuring suppliers align with sustainability goals is easier with IoT for green logistics. IoT-powered monitoring systems provide real-time transparency into supplier operations, helping businesses select responsible partners.

Key IoT-enabled supplier management features include:

- Emission tracking across supplier networks to ensure compliance with environmental standards.

- Energy efficiency monitoring to identify high-impact areas for sustainability improvements.

- Ethical sourcing verification through IoT-driven material origin tracking.

Basically, IoT supply chain sustainability can be achieved in numerous mutually complementary ways. Naturally, some businesses, like transportation companies, may be more interested in carbon emission monitoring, while others, such as manufacturers, are more concerned about smart packaging. Discovering where green supply chains with IoT can be of best usage is the first step to digital transformation.

Explore additional details on how to use IoT in supply chain management in another blog post by Intelliarts.

Common AI in green chains implementation issues

As a continuation of the description of IoT supply chain sustainability issues, we need to mention what challenges exactly make it difficult to apply AI technologies in green chains. Recommendation on how those issues can be addressed is included:

#1 Data accuracy and bias

AI models rely on data, but inaccurate or biased inputs can lead to flawed sustainability decisions. This impacts carbon tracking, waste reduction, and supplier evaluation.

Solution: Use diverse, high-quality datasets and regularly audit AI models to eliminate bias and improve decision accuracy.

You may be interested in learning additionally about data preparation in ML, which is explored in detail in another our blog post.

#2 High energy consumption of AI models

AI algorithms, especially deep learning models, require vast computing power, increasing carbon emissions and offsetting sustainability benefits.

Solution: Optimize AI algorithms for energy efficiency and use green data centers powered by renewable energy.

#3 Lack of standardized sustainability metrics

AI struggles with inconsistent definitions of sustainability across industries, making it hard to compare and track green supply chain progress.

Solution: Develop industry-wide AI-friendly sustainability frameworks for uniform reporting and analysis.

#4 Ethical and transparency concerns

AI-driven sustainability decisions often lack transparency, making it hard to validate eco-friendly claims and ensure ethical sourcing.

Solution: Implement explainable AI (XAI) models that provide clear insights into decision-making processes.

#5 AI model scalability across global supply chains

AI solutions may work in limited regions but struggle to scale across diverse global operations with varying regulations and infrastructures.

Solution: Develop modular AI models adaptable to different supply chain environments and compliance requirements.

#6 Security risks in AI-driven supply chains

AI-powered logistics and sustainability platforms are vulnerable to cyber threats, which can manipulate data or disrupt operations.

Solution: Strengthen AI cybersecurity with encryption, access control, and regular audits. For physical security, an access control system can also protect critical infrastructure by controlling who can enter sensitive areas.

In essence, it’s possible to minimize concerns and limitations of AI and IoT green supply chains. However, it often requires AI development services from a trusted dev partner to handle technical aspects.

Real-life IoT solutions for sustainable supply chains

Let’s get through two real-world success stories of how famous companies faced sustainable supply chain issues and addressed them through software solutions:

Blustream’s IoT-enabled storage monitoring system: Success story by Intelliarts

Background:

Blustream Corporation needed to prevent product spoilage due to temperature and humidity fluctuations in its supply chain. The company partnered with Intelliarts to develop a mobile app synced with IoT sensors for real-time condition monitoring.

Solution:

Intelliarts built an app that connects to IoT sensors via Bluetooth, tracking temperature and humidity. It sends real-time alerts and provides analytics to help businesses optimize storage environments.

Results:

The solution reduced product spoilage and storage risks, resulting in cost savings and improved supply chain efficiency. It also expanded Blustream’s B2B customer base.

Walmart’s IoT-enabled food safety system

Background: Walmart needed to improve food safety and reduce waste in its supply chain, especially for perishable items like fruits and vegetables.

Solution: The company deployed IoT sensors in refrigerated trucks and storage units. These sensors track temperature, humidity, and shelf life, ensuring optimal conditions during transportation. Any deviations trigger alerts, allowing quick corrective action.

Results: Walmart cut food waste by 15%, improved compliance with safety regulations, and ensured fresher products for customers. The IoT system also reduced energy consumption in refrigeration, aligning with Walmart’s sustainability goals.

Maersk’s smart containers for efficient shipping

Background: Global shipping giant Maersk faced challenges in tracking container conditions, leading to inefficiencies, spoilage, and delays in the supply chain.

Solution: Maersk introduced IoT-enabled “smart containers” equipped with real-time tracking sensors. These devices monitor temperature, humidity, and location, providing instant data to logistics teams. The system integrates with cloud analytics to optimize routes and prevent product spoilage.

Results: The implementation reduced cargo loss by 30%, improved supply chain visibility, and enabled predictive maintenance. Maersk’s customers gained real-time insights into shipments, increasing efficiency and reducing delays, contributing to more sustainable logistics.

Final take

IoT green supply chain technologies can be reinforced with advanced analytics, real-time monitoring, and predictive capabilities. It offers optimized energy use, enhanced transparency, and minimized waste through data-driven decision-making. They enable precise demand forecasts, efficient logistics, and automated sustainability compliance, reducing carbon emissions and operational costs. This approach creates a more sustainable and resilient supply chain ecosystem.

Having a trusted tech partner for your IoT green supply chain project is half the battle. Should you need professional assistance, don’t hesitate to reach out to the Intelliarts team. With more than 24 years of experience and hundreds of projects under our belt, we are ready, willing, and able to provide technical consulting, execution, and support.

FAQ

1. How can AI and IoT fix inefficiencies in our supply chain?

AI and IoT solutions enhance supply chain efficiency by automating real-time tracking, optimizing logistics routes, and reducing resource waste. IoT in sustainable supply chain management improves demand forecasting, prevents inventory shortages, and lowers fuel consumption through route optimization. AI-powered analytics detect bottlenecks, ensuring green supply chain optimization with IoT for maximum efficiency.

2. What ROI can we expect from AI & IoT in a green supply chain?

ROI depends on scale, but businesses typically see cost reductions of 10-30% through predictive analytics, energy savings, and automated operations. IoT for green logistics minimizes waste, optimizes fuel usage, and prevents equipment failures. Faster delivery times and IoT supply chain sustainability improvements boost customer satisfaction and regulatory compliance, increasing long-term profitability.

3. Can you share case studies of AI & IoT for sustainability?

Yes, we have helped EV charging networks and fleet operators optimize energy consumption and reduce costs. Our EV fleet management system improved charging efficiency and enabled at-home charging cost compensation, while our smart power management platform helped businesses schedule power limits and lower expenses in sustainable logistics with IoT.