Solution Highlights

- Provided an ML-powered solution for predicting the degradation level of hydraulic system components

- Allowed for the proper maintenance of the hydraulic system

- Achieved average accuracy of 98% for each ML model

- Benefited the company with cost reduction and lower downtime

- Conducted staff training on how to use the ML solution properly in production

About the Project

Customer:

A large manufacturing company (under NDA) has a complex hydraulic system as a part of their facility. The manufacturer cares about the proper maintenance of this system to be able to reduce costs and lower the probability of unexpected downtime.

Challenges & Project Goals:

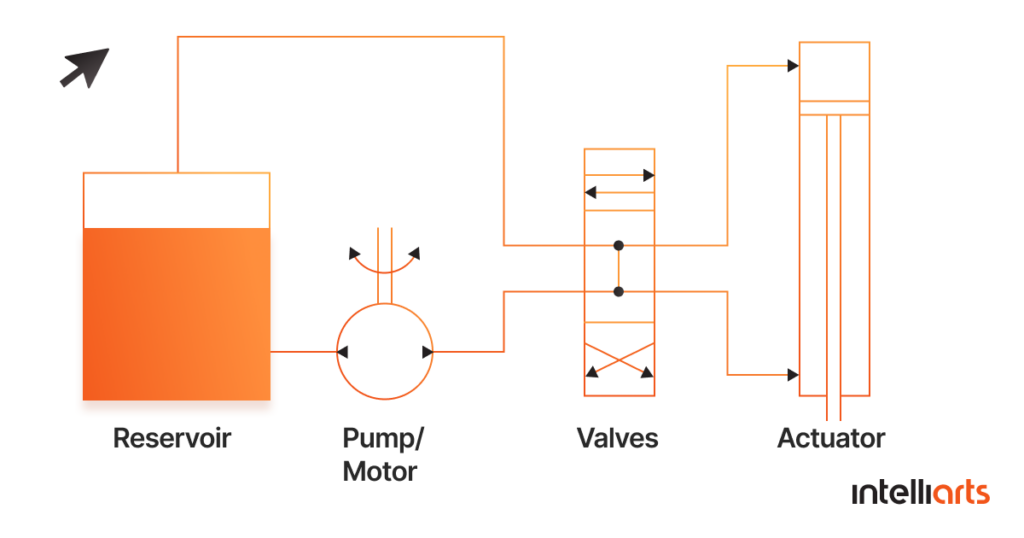

The project aimed at addressing the periodic malfunctioning of the specific components of the customer’s hydraulic system (cooler, valve, pump, and hydraulic accumulator). The latter disrupted the whole facility and, as a result, brought extra maintenance costs and affected the manufacturer’s operations.

Solution:

Within the scope of our cooperation, we implemented a machine learning-based system that could predict the degradation level of specific components with a high level of accuracy. Our solution was composed of four separate ML models for each of the components with an average prediction accuracy of 98%.

Business Value Delivered:

Intelliarts team delivered an efficient ML solution that proved to be truly accurate in its results. The solution helped the manufacturer predict malfunctions of the hydraulic system’s components (cooler, valve, pump, and hydraulic accumulator). In the long run, it also ensured proper equipment maintenance and benefited the manufacturer with cost reduction, improved productivity, safety, and lower downtime.

Technology Solution

We composed the four ML models that allowed the manufacturer to predict the degradation level of the key components of the hydraulic system. During the project, our data scientists:

- Processed the records from IIoT sensors in the dataset and conducted detailed data analysis to make sense of the data by uncovering trends and patterns.

- Solved the problem of model overfitting caused by a big amount of features in the system. Since this issue could affect the model’s ability to generalize, we needed to prevent overfitting.

- Experimented with different machine-learning algorithms until we chose the XGBoost classifier, StratifiedKFold, and RandomForestClassifier for the four ML models we built, as these showed the most promising results on the available data.

- Increased the prediction accuracy on test sets to 98% for each of the four ML models by training and fine-tuning the models.

- Developed API endpoints, triggered after each load cycle of the system. This should help the manufacturer with the model monitoring to identify when the performance drops and the model requires retraining or tuning.

- Conducted training sessions to educate the personnel on how to use the ML solution in their day-to-day procedures by enlisting the help of the management.

Business Outcomes

By the end of this project, the customer was completely satisfied with the results:

- We provided an efficient ML-powered solution for predicting a degradation level in the hydraulic system. This allowed for proper maintenance of the hydraulic system in advance and, hence, benefited the company with higher productivity and reduced downtimes.

- All four models reached our original target of 95% of accuracy. Plus, the Intelliarts team continues to keep in touch with the manufacturer so, if it notices any significant changes in the data, we’re always ready to assist and retrain the models for better business outcomes.

- As a part of the full-cycle project, we established monitoring of the model performance as well as developed API endpoints. Hence, the plant’s operators get immediate notifications about the inefficiencies of the hydraulic system and which specific component requires their attention at the moment.