Solution Highlights

- Developed ML models for demand forecasting, optimizing procurement and resource management

- Leveraged advanced data analytics to derive actionable insights from the manufacturer’s data

- Seamlessly integrated the solution into the manufacturing system for easy accessibility

- Ensured model results were understandable for non-technical personnel, improving marketing campaign planning and budgeting

About the Project

Customer:

Our partner (under NDA) is a global manufacturer and distributor of electronic interconnects, including connectors, cables, optics, rugged and power solutions, and more. This company is a leading service provider in the electronic interconnect industry with a comprehensive product line ranging from the integrated circuit to the board and beyond.

Challenges & Project Goals:

Due to their large size and scale of production, the company lagged behind the competitors in demand forecasting and procurement planning. For example, the manufacturer could produce 50 types of cables but often didn’t have all of them in stock. In contrast, smaller resellers with well-established marketing strategies had better sales by consistently stocking the right cables, even though they sourced these products from our partner. This inconsistency usually meant missed sales opportunities and customer dissatisfaction for our partner.

By reaching out to Intelliarts, our partner aimed to address these issues to improve operational efficiency and maintain a competitive edge. Our project goals were to detect trends and patterns in the manufacturer’s data, predict demand, improve forecasts and stock availability.

Solution:

By collaborating closely with the customer, we developed a machine learning (ML) prediction and forecasting engine. The solution consists of two main components:

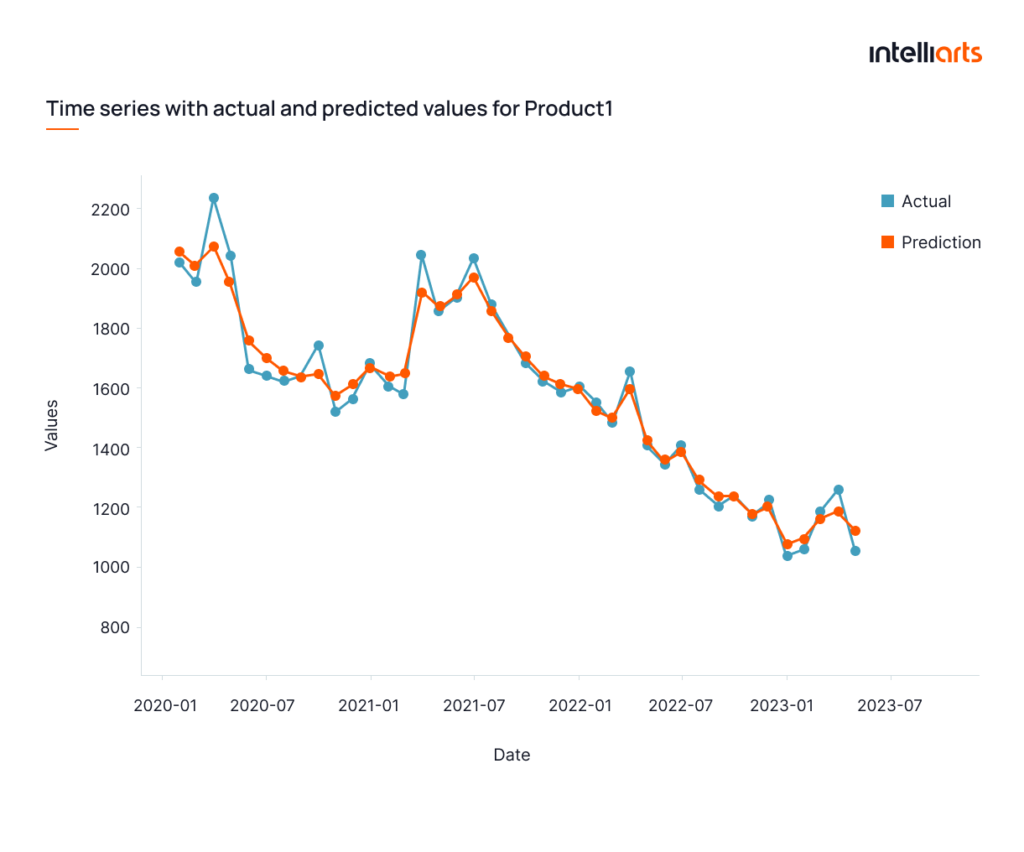

- ML model for sales/demand forecasting: This model helps our partner anticipate their future purchasing needs and plan accordingly. Our ML team analyzed the manufacturer’s sales funnel and applied time series prediction methods based on its features to predict sales. This enables the company to manage resources more efficiently, reducing costs and waste.

- Effective data analytics: The manufacturer collects and stores vast amounts of real-time data from multiple sources. They wanted to leverage this data to gain actionable insights and improve decision-making. Our solution facilitates the analysis of this data, providing the necessary insights to enhance operational efficiency.

ML Development, Data Analysis, Cloud Services, Big Data, Business Intelligence & Analytics, Data Science

Technology Solution

In this project, the Intelliarts ML team implemented data analytics and ML models for procurement planning and sales predictions. We began with a thorough business understanding to go deeper into the business problem and customer’s core needs, as well as to determine the best approach to take.

Data preparation and analysis

Our data scientists analyzed the manufacturer’s data to understand the relationship between different variables. This included data on product availability, pricing, quantities, and user behavior. One of the core challenges at this stage was a large volume of data and its sparsity. It was also critical to clean the data to filter out the less important products like those that had not been bought for a long time or brought little revenue.

Through this data analysis, we uncovered many insights valuable for the company’s decision-making. For example, we compared our customer’s pricing with competitors and, as expected, found products with high sales due to lower prices. But we also discovered products with high prices and high sales, which were driven by historical contracts rather than market demand. To explain, large companies continued to buy from our partner despite non-optimal pricing due to established relationships. This insight was crucial for our customer to understand and refine their business model, though it also created extra noise in the data analyzed.

At the same time, our most important insight was identifying a design cycle for each group of electronic interconnects sold by the manufacturer. This highlighted a long sales cycle: an engineer visits the website, downloads the product’s CAD (computer-aided design) or 3D model, buys a small quantity to prototype their own product, and then returns for industrial-scale purchases after successful results. As we discovered, this design cycle varied by product and could last from a few weeks to up to half a year.

Model development

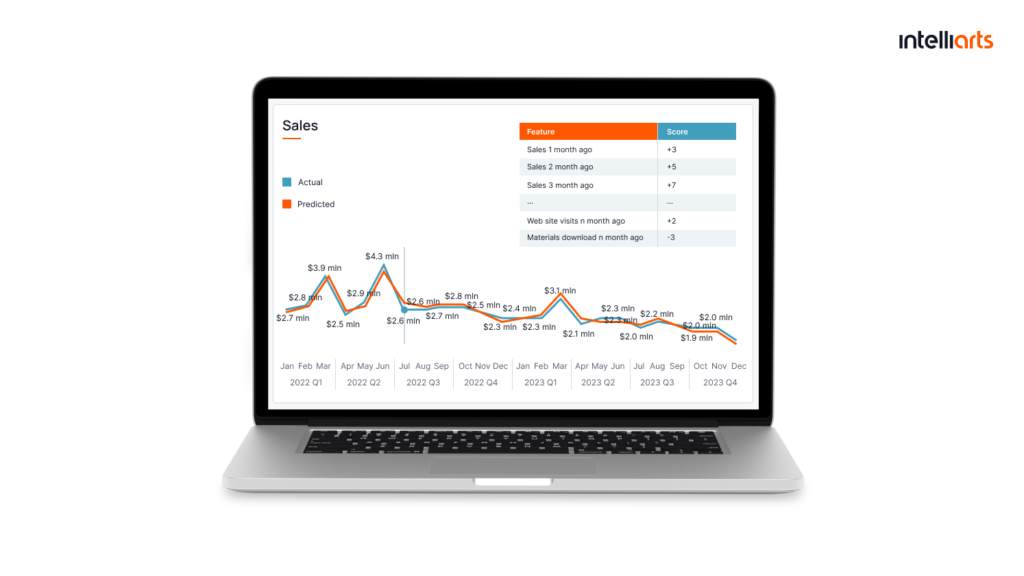

With insights from the data analysis, our ML team identified the design cycle for each product group, which helped us further in modeling. Using sales funnel features, we generated lab features to build classical time series models to predict sales and demand for different products. As evident from the chart below, the model achieved over 90% accuracy, proving highly beneficial for procurement forecasts.

We then integrated our solution into our partner’s dashboards, enabling employees to view and use the ML model results easily. One of the main challenges of modern machine learning is to interpret complex model results and make them understandable to non-technical users.

By using data visualization dashboards, our team did not only show model predictions but also explained the factors influencing the results. For example, the manufacturer could see predictions for growing demand for a product and understand the reasons behind it, such as a rise in sales linked to a product’s design cycle.

Business Outcomes

Together with the customer, we built an ML prediction and forecasting engine to help the manufacturer with demand prediction and procurement planning. The manufacturer contacted us with an idea of what needs to be improved, while the Intelliarts team combined it with data analytics to deliver a solution with real business benefits. We also ensured that the model results were understandable and easy to interpret for the personnel.

Due to the long design cycle of most of the manufacturer’s products, we’re still waiting for the first revenue estimates following the solution implementation. Nonetheless, the customer has already experienced tangible business improvements, particularly in marketing budget planning.

The marketing team is very grateful for the insights we provided about the reasons behind the growing or decreasing demand for various products. These insights have helped them launch new marketing campaigns more effectively or, conversely, avoid investing in campaigns for products that are unlikely to yield significant sales.

Our ML solution is also expected to provide the manufacturer with several key benefits:

- Cost optimization: By accurately predicting future demand, the manufacturer can purchase materials in optimal quantities, avoiding overstocking or stockouts. This should reduce holding costs, minimize waste, and improve negotiation power with suppliers due to more precise and timely procurement planning.

- Operational efficiency: Ensuring the right materials are available at the right time will help our partner reduce production delays and downtime. As a result, the company should experience smoother production processes and more reliable delivery schedules.

- Decision-making: Our ML solution provides data-driven insights, helping to analyze trends and patterns in the manufacturer’s data. This supports more informed decision-making, enabling managers to anticipate market trends and adjust strategies accordingly.