Over the past decade, electric vehicles have gained an increased presence and even some local domination in the passenger transportation market. That’s due to a combination of sustainability concerns and regulatory changes. But is this true for EV charging trucks as well, and can truck EV charging potentially be an additional opportunity for the energy infrastructure business?

In this post, you’ll discover more about the state of the EV truck industry and why electric truck charging is a game-changer for charging businesses. Besides, you’ll find out about solutions for electric truck charging infrastructure as well as key business challenges and possible solutions to them.

Why electric trucks are gaining momentum

Electric trucks are commercial or utility vehicles powered by electric motors instead of internal combustion engines. They are powered through electric truck charging, which is, in a broad sense, a higher-power EV charging.

Just to clarify the type of vehicles this post covers, let’s take a look at three categories of electric trucks:

- Light-duty electric trucks (LD e-trucks). Electric pickups, small delivery vans, and utility service vehicles. Mostly used for urban delivery, personal transport, and light hauling.

- Medium-duty electric trucks (MD e-trucks). Box trucks and cargo vans, refuse trucks, utility and construction trucks, and airport ground service vehicles. Ideal for city logistics and municipal operations.

- Heavy-duty electric trucks (HD e-trucks). Electric semis and tractor-trailers, long-haul and regional delivery trucks, construction haulers, cement mixers, and mining/logging trucks. Designed for industrial and long-range heavy transport.

Before proceeding any further, let’s find out how advantageous EV trucks are compared to traditional trucks in simple bullet points:

- Lower fuel and maintenance costs

- Zero tailpipe emissions

- Quiet operation

- Financial EV incentives

- Suitable for stop-and-go driving

What’s also essential to understand is how electric trucks are different from other passenger EVs, from a positive perspective:

- Bigger batteries allow handling heavier loads and often covering longer distances, which is especially true for light-duty vehicles.

- Handle longer routes suitable for deliveries or freight across cities or regions.

- Higher power needs due to weight, towing, and industrial functions.

- Stronger chassis and components that are built for durability under heavy use.

- Slower acceleration and less agility compared to smaller passenger EVs.

However, every advantage comes with a limitation. That’s why, when building a business, including EV charging one, around electric trucks, you need to keep in mind the following cons:

- High upfront investment cost

- Notably longer charging times

- Shorter driving range under heavy load for most medium and heavy-duty vehicles

- Faster battery degradation

- Higher power input requirements, e.g., up to 250 kW for Tesla Model 3 supercharger vs. up to 1,000 kW for Tesla Semi electric truck megacharger

As you can conclude, EV trucks are looking as a promising replacement for traditional vehicles, while naturally being more suited to anything related to moving cargo or fulfilling utility duties compared to lightweight regular and EV vehicles.

Explore the EV fleet management software success story by Intelliarts.

Electric trucks industry overview

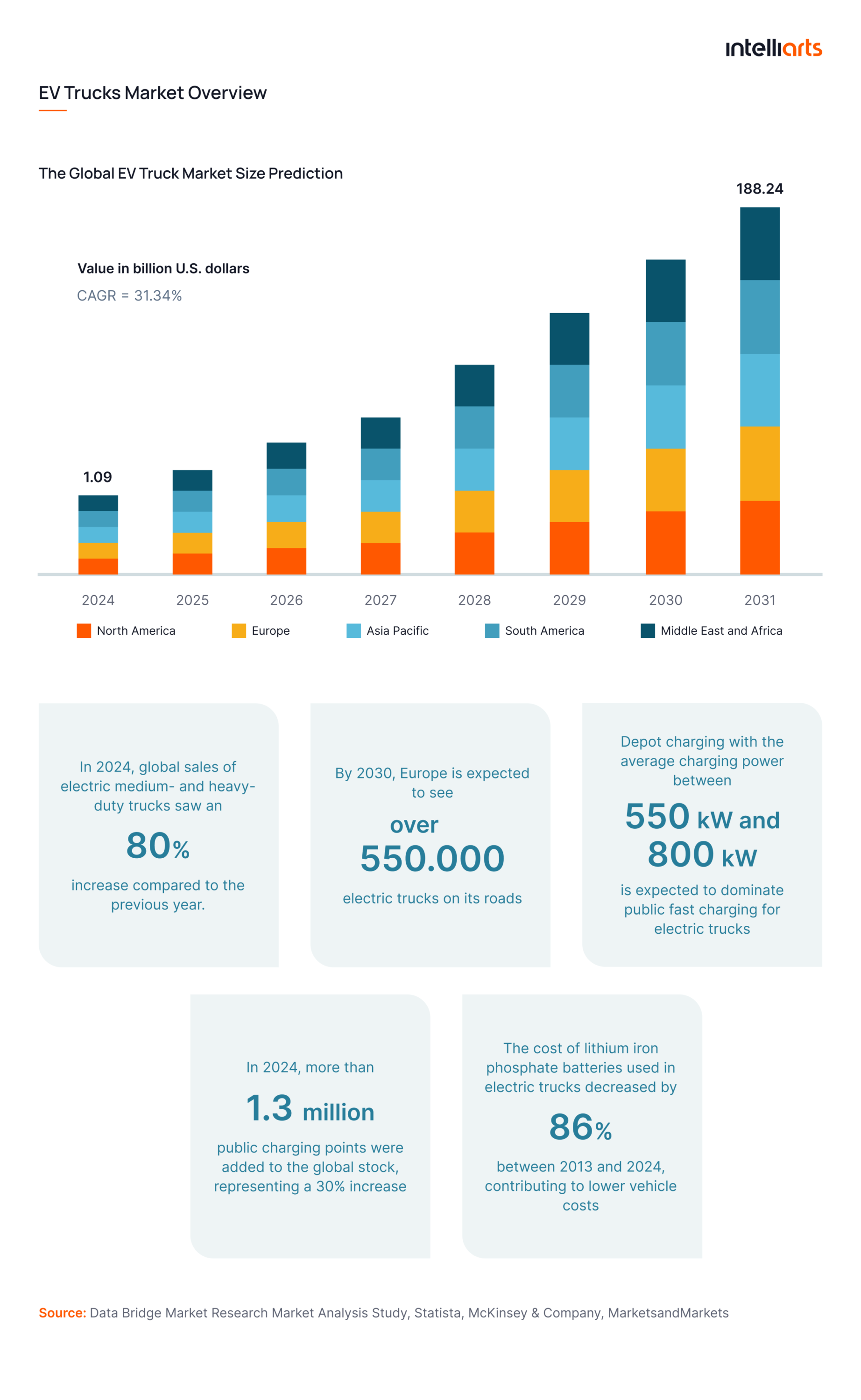

With the above information in mind, we need confirmation that fast charging of electric trucks is a promising niche. Here’s a breakdown of stats revealing that electric trucks are indeed growing in popularity as a passenger transportation solution:

Why fast EV truck charging is a game-changer

It’s easy to overlook the significance of fast electric truck charging solutions. That’s because most businesses are used to heavy-duty machinery equipped mostly with diesel engines, which don’t face downtime issues. However, the considerations are vastly different when it comes to electric truck charging.

The need to charge electric trucks faster

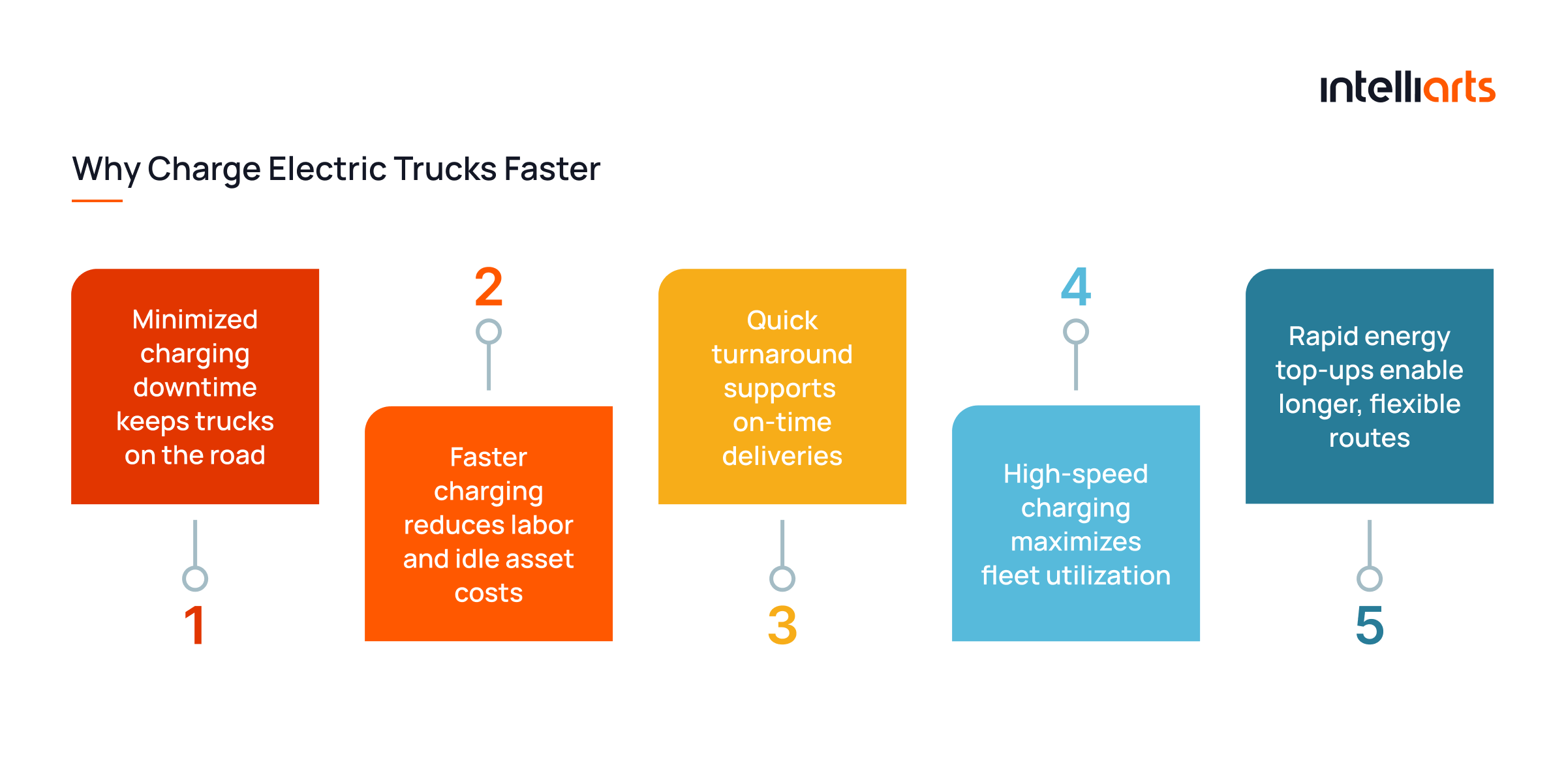

Fast charging for electric truck fleets directly impacts uptime, delivery efficiency, and overall profitability. Unlike passenger EVs, trucks are commercial assets expected to operate for long hours with minimal interruptions. The infographics below reveal all points that evidence the strong need to charge electric trucks faster:

Where are we today?

The need to have fast electric truck charging is well understood already. However, we also need to have an insight into where the world is, as of now, in terms of covering EV charging needs and EV charging solutions. Here are the stats to consider:

- China, as a country accounting for most EV truck usage, has a share of fast chargers of only around 45%.

- The U.S. had approximately 204,000 public and workplace chargers by the end of 2024, with DC fast chargers increasing by 56% from the previous year.

- BP Pulse has established Europe’s first public charging corridor for electric trucks along the Rhine-Alpine route, featuring ultra-fast 300kW chargers capable of adding up to 200 km of range in 45 minutes.

As we can conclude, the situation with electric truck charging infrastructure is not ideal, but it’s gradually improving. There are plenty of opportunities for charging businesses to enter the niche and start offering fast electric truck charging solutions themselves.

Top 4 emerging fast truck charging solutions

For the main take, let’s focus on four technology solutions for charging electric trucks. This will help to understand the niche better, as for 2025 and potentially beyond, and delve into related critical considerations.

Truck charging standards

In the early days of EV charging, the interoperability of connectors was problematic. At the same time, chargers with sufficient power were difficult to acquire. That’s when standards stepped in. As of now, there’s a range of protocols and standards that manufacturers of EV chargers follow and businesses utilize to select suitable chargers for their electric truck charging infrastructure. Here they are:

- MCS (Megawatt Charging System). MCS is developed for heavy-duty trucks to enable ultra-fast DC charging up to 3.75 MW. It is expected to become the global standard for long-haul electric freight.

- CCS (Combined Charging System). CCS supports both AC and DC charging through one connector and is widely used for passenger EVs and medium-duty trucks. It’s a foundational standard in Europe and North America for public and depot charging.

- OCPP (Open Charge Point Protocol). OCPP is a communication standard that enables interoperability between EV chargers and backend systems. It allows charging stations from different vendors to be managed from a single platform.

- SAE J1772. SAE J1772 specifies the AC Level 1 and Level 2 charging connectors used in North America for light- and medium-duty EVs. It is the default connector for most non-Tesla EVs in the U.S. and Canada.

- IEC 61851. IEC 61851 is the international standard for EV conductive charging systems, covering safety and charging modes. It establishes how EVs and chargers should interact to ensure reliable and safe operation.

Explore Intelliarts’ success story on openADR implementation for load management for an extra insight into EV solutions from expert developers.

Smarter energy resource usage on multiple levels

For operators planning electric heavy duty truck charging solutions, smarter energy orchestration is the difference between theoretical capacity and dependable day-to-day uptime. While “smarter” usage may seem like a rather vague term, it actually hints at a range of technology solutions that electric truck charging businesses may consider implementing. Here they are:

#1 On-site energy storage

On-site energy storage refers to a system, typically using large batteries, installed at a facility (like an EV truck charging station) to store electricity for later use.

These systems charge using electricity from the grid or renewable sources (like solar) during low-demand or low-cost periods, making them a valuable element of electric truck and heavy duty charging market development. This stored energy can then be used during high-demand periods, reducing peak load charges and enhancing grid resilience. It also ensures continued operation during outages or instability.

#2 Solar integration

Solar integration means installing solar panels at a facility, such as an EV truck charging station, to generate electricity from sunlight.

An on-site renewable energy source can power chargers directly or charge an energy storage system. It helps reduce dependence on the grid, cut energy costs, and lower carbon emissions. Solar systems can operate alone or alongside batteries, providing clean, sustainable energy for daily charging operations. But clean energy offers more than cost efficiency. Actually, solar integration may make a business eligible for better tariffs or tax reductions.

#3 Smart load balancing

Smart load balancing is a system that automatically distributes electricity across multiple EV chargers based on real-time demand.

Smart load balancing distributes available electrical capacity across multiple chargers based on real-time demand and usage patterns. This prevents overloading the grid connection and ensures efficient charging without the need for costly infrastructure upgrades. It allows priority scheduling for certain vehicles and optimizes power usage dynamically, which is critical when managing fleets with varying arrival times and charging needs.

Explore load balancing additionally in another blog post by Intelliarts experts.

Mobile and temporary charging units

Mobile charging units are portable EV chargers that don’t require permanent infrastructure and are ideal for temporary fast charging for trucks, especially in remote depots or logistics hubs. These systems can be deployed quickly at depots, events, or construction sites to serve temporary needs. They’re especially useful during fleet transitions, infrastructure upgrades, or when operating in remote areas without grid access. Let’s get through the main use cases of mobile charging units:

Use cases:

- Fleet pilots without infrastructure commitment

- Temporary charging at new or remote depots

- EV support for construction and infrastructure projects

- Power for leased or seasonal delivery fleets

- Event-based logistics and pop-up operations

- Emergency relief in disaster zones or grid outages

- OEM truck demos or mobile EV service stations

Integrated fleet management platforms

Integrated fleet management platforms combine EV charging control with vehicle tracking, energy usage, and operational planning, turning charging from a manual task into a data-driven advantage. These platforms help logistics operators reduce costs, avoid charging bottlenecks, and optimize route scheduling based on real-time vehicle and charger availability. So, are there fast charging options for electric trucks? Yes, integrated platforms like these provide visibility and management across the full charging ecosystem.

Examples of platforms:

#1 Geotab

Offers real-time EV battery data, smart charging analytics, and route planning tools tailored to electrified fleets.

Website: www.geotab.com

#2 ChargePoint Fleet

Combines hardware and software to manage charging, vehicle readiness, and energy usage at scale — used by Amazon and FedEx.

Website: https://www.chargepoint.com/

#3 Shell Telematics (formerly Greenlots)

Supports load balancing, depot optimization, and integrates with major fleet platforms via open APIs.

Website: www.shell.com/

Note. An alternative to using a management platform available on the market is custom solution development. Regardless of the choice, you will still need a trusted provider like Intelliarts to integrate or develop from scratch and then integrate a platform into your charging infrastructure and IT system.

Discover how Intelliarts created an EV charging management platform for EVIQ just in 6 months, which is significantly faster than the average industry standard.

Key challenges for EV truck businesses and solutions to them

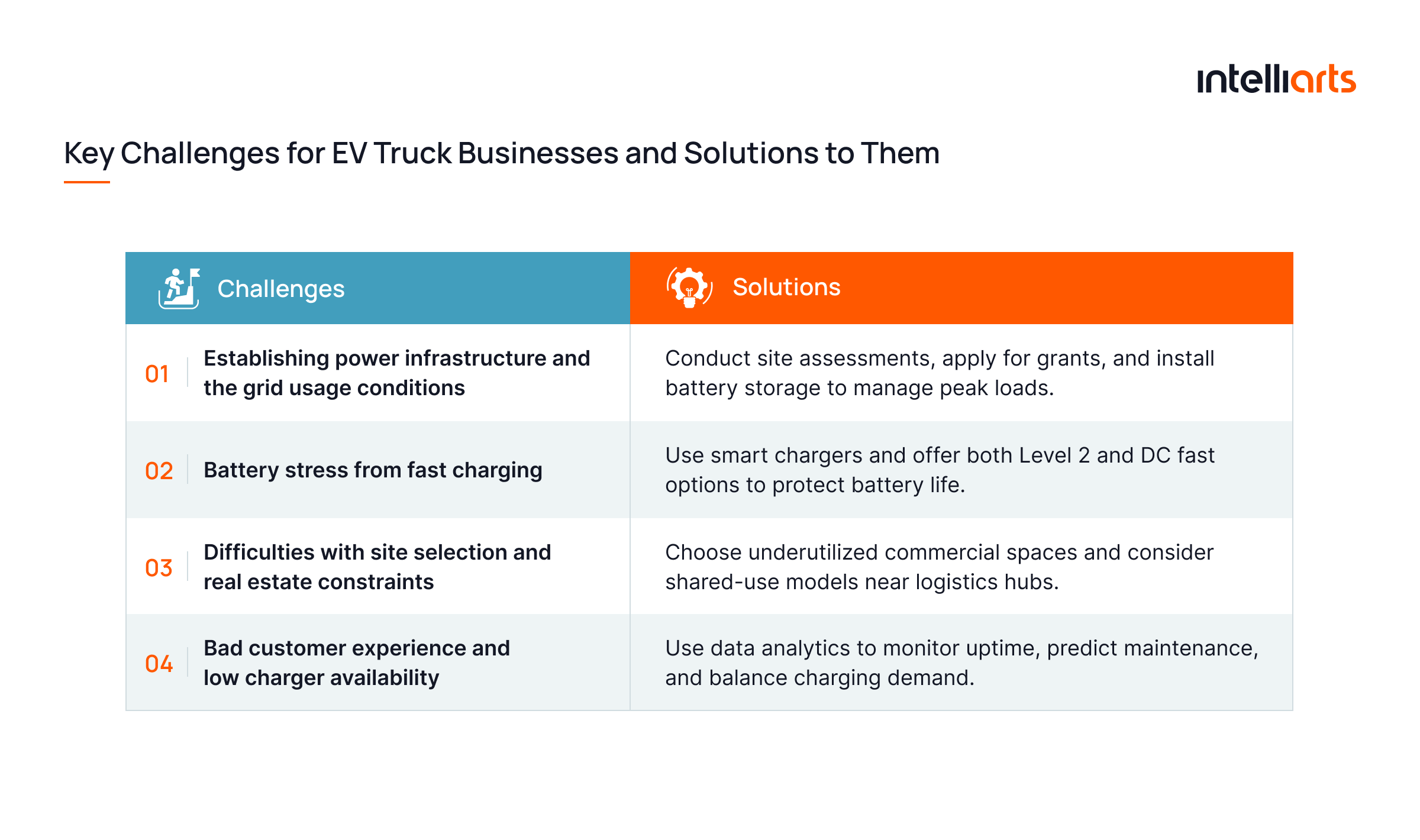

Any business project comes with possible challenges and difficulties. Let’s review the top four issues that providers of electric truck charging solutions and infrastructure may face within their business model:

#1 Establishing power infrastructure and the grid usage conditions

To charge electric trucks at scale, especially with rapid charging solutions for e-truck fleets, businesses must navigate the limitations of existing electrical infrastructure. Most commercial sites aren’t equipped to handle the energy demands of high-power charging. Therefore, installing an electric truck charging station often requires significant upgrades, such as new substations, high-capacity transformers, and power lines.

Solution: Start by conducting a site readiness assessment with your utility provider. Explore grants or incentives for infrastructure upgrades. For large fleets, consider adding battery storage systems to manage peak demand and reduce pressure on the grid.

#2 Battery stress from fast charging

Frequent use of fast chargers without proper energy management can shorten the lifespan of truck batteries. This is a key concern in electric truck charging solutions since charging too quickly can cause overheating and degrade cells, especially in older or lower-grade batteries.

Solution: For owners of EV vehicles, it can be advised to choose smart electric truck chargers that automatically adjust charging speeds based on battery condition and temperature. As for charging businesses, it’s recommended to offer mixed charging speeds (Level 2 and DC fast) to balance efficiency with battery longevity.

#3 Difficulties with site selection and real estate constraints

Finding locations suitable for electric truck charging stations is not as simple as placing a charger in a parking lot. The ideal site must have sufficient space for trucks to maneuver, enough electrical capacity, and convenient access to major routes or logistics hubs. Urban environments may pose additional challenges due to land costs and zoning restrictions.

Solution: Target underutilized commercial spaces near logistics corridors or warehouse districts. Partner with property owners who can benefit from added foot traffic or new revenue streams. Consider shared-use models with other fleet operators to increase utilization rates.

#4 Bad customer experience and low charger availability

Whether you operate a public station or a depot, broken chargers or long wait times reduce customer satisfaction and trust in your electric truck charging solutions. That’s usually the lack of real-time data that leads to such issues in pre-planning and in scaling business stages when decisions regarding data analytics systems and their usage are made.

Solution: For an electric truck charging business, having data analytics software is obligatory. Using data analytics, businesses can monitor charger status in real time, predict maintenance needs, and balance loads to avoid peak-hour delays. This helps deliver a better customer experience and improve ROI as your network grows.

Final take

The electric truck charging market is quickly evolving, driven by sustainability goals, fleet electrification, and regulatory shifts. Fast charging, smart energy management (like storage, solar, and load balancing), and data-driven infrastructure planning are key to success. Although challenges such as grid upgrades and battery stress remain, businesses that embrace innovation and strategic site development can capture this emerging opportunity.

Looking for a trusted service provider to help you with software for your electric truck charging stations? Don’t hesitate to reach out to Intelliarts. With 90% of recurring customers, over 25 years of presence in the software industry, and a focus on long-term partnership, we can cover your development needs.

FAQ

What is the difference between fast charging and rapid charging?

Fast charging typically refers to AC charging up to 22 kW, while rapid charging means DC charging at 50 kW or higher. For electric trucks, rapid charging is essential to minimize downtime. Our electric truck charging solutions support both options.

How do we estimate the cost of installing fast charging at our depots or facilities?

It’s recommended to assess charger types, power capacity, site upgrades, and utility connections. The cost to install an electric truck charging station varies by site but typically starts at $50,000–$150,000 for rapid charging setups.

What kind of charging infrastructure would we need to support electric trucks in our fleet?

You’ll need electric truck chargers ranging from 150 kW to 1 MW, backed by transformers, switchgear, and smart charging software. Scalable electric truck charging infrastructure is essential for large fleets.