There was a time when the idea of “plugging in” your car sounded like a punchline. It used to be a futuristic experiment that surely wouldn’t survive in the real world. Even the worries seemed comical: What if the battery dies halfway? What then?

Well, jokes on us. Electric vehicles have moved from a curiosity to a daily necessity so seamlessly that it’s now hard to imagine the road without them. With global EV sales reaching around 14 million, another story unfolds just as quickly: the demand for charging points is rising far faster than the supply.

And that gap isn’t random. Installing chargers is expensive, technically demanding, and often slowed down by infrastructure limitations.

The Intelliarts team has developed EV charging software for the last 9 years, and we’re ready to share our knowledge. In this article, we’ll explore how your charging ecosystem can be optimized. How costs can be reduced, efficiency improved, and the path to widespread EV adoption made smoother for everyone.

What EV costs are there to optimize?

But before exploring ways to reduce costs, it helps to understand what actually drives the price of an EV charging station. The overall cost typically consists of several key components:

1. Installation expenses

This covers both the cost of the charging hardware and the equipment required to set it up on-site. Depending on the location, the project may also involve upgrades to the electrical system (e.g., boosting power capacity). Labor, permitting, and construction requirements also affect final costs, but they are one-time investments.

Hardware (and its maintenance, which we’ll cover later) remains the most significant single cost factor. Today’s charging stations generally fall into three categories:

- Level 1 (AC 120V): Slow charging via standard household outlets

- Level 2 (AC 240V): Faster charging commonly used in offices and public locations

- Level 3 (DC fast charging): High-speed charging typically installed at fleet depots, highways, or dedicated hubs

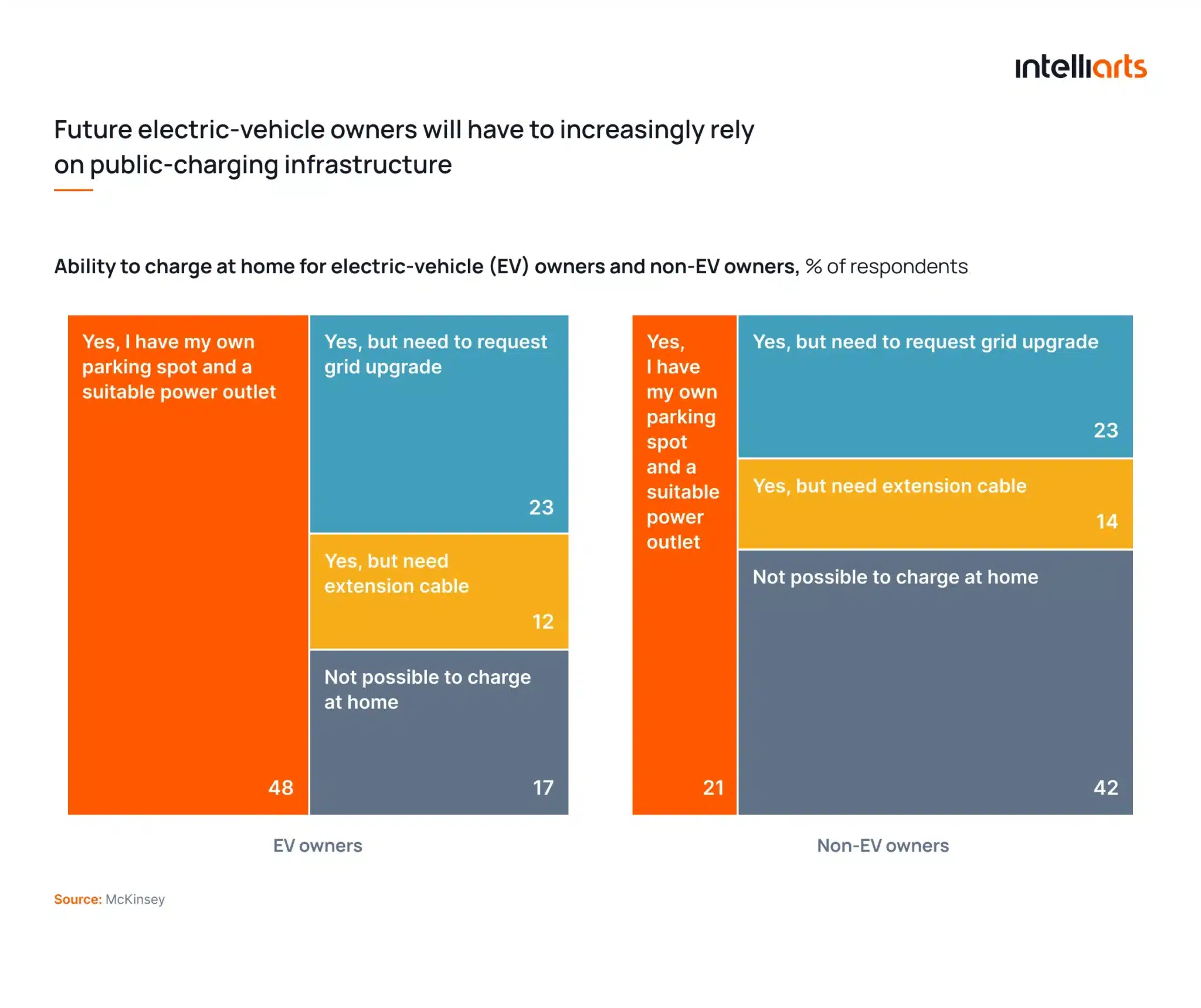

For now, Level 1 and Level 2 chargers remain the most common. Why? According to McKinsey, around 48% of current EV owners globally already have access to private parking with a suitable power outlet. Another 35% say home charging would be possible with minor adjustments, while only 17% report that home charging isn’t an option at all.

Although if we look at potential EV owners, who will ultimately dictate market trends, the situation is very different. As electric vehicle adoption grows, public charging will play an increasingly critical role, as many future EV owners will lack sufficient space or electrical capacity at home to charge their vehicles. According to survey results, 42% of respondents who do not currently own an EV expect that home charging will not be available to them.

Also, McKinsey predicts “advanced battery technology specifications pairing long driving range with superfast recharging times, sometimes enabled by 800-volt system architecture. This means that technology is expected to advance to enable longer driving times and faster charging. In the near future, we may be able to charge our EVs as quickly as we refuel a tank.

However, before that time comes, it still makes a lot of sense to invest in charging infrastructure, as demand is far from being met.

2. Maintenance requirements

To keep charging stations safe and reliable, routine maintenance is essential. This may involve updating software, fixing hardware, and ensuring the system runs smoothly for users.

- Hardware maintenance

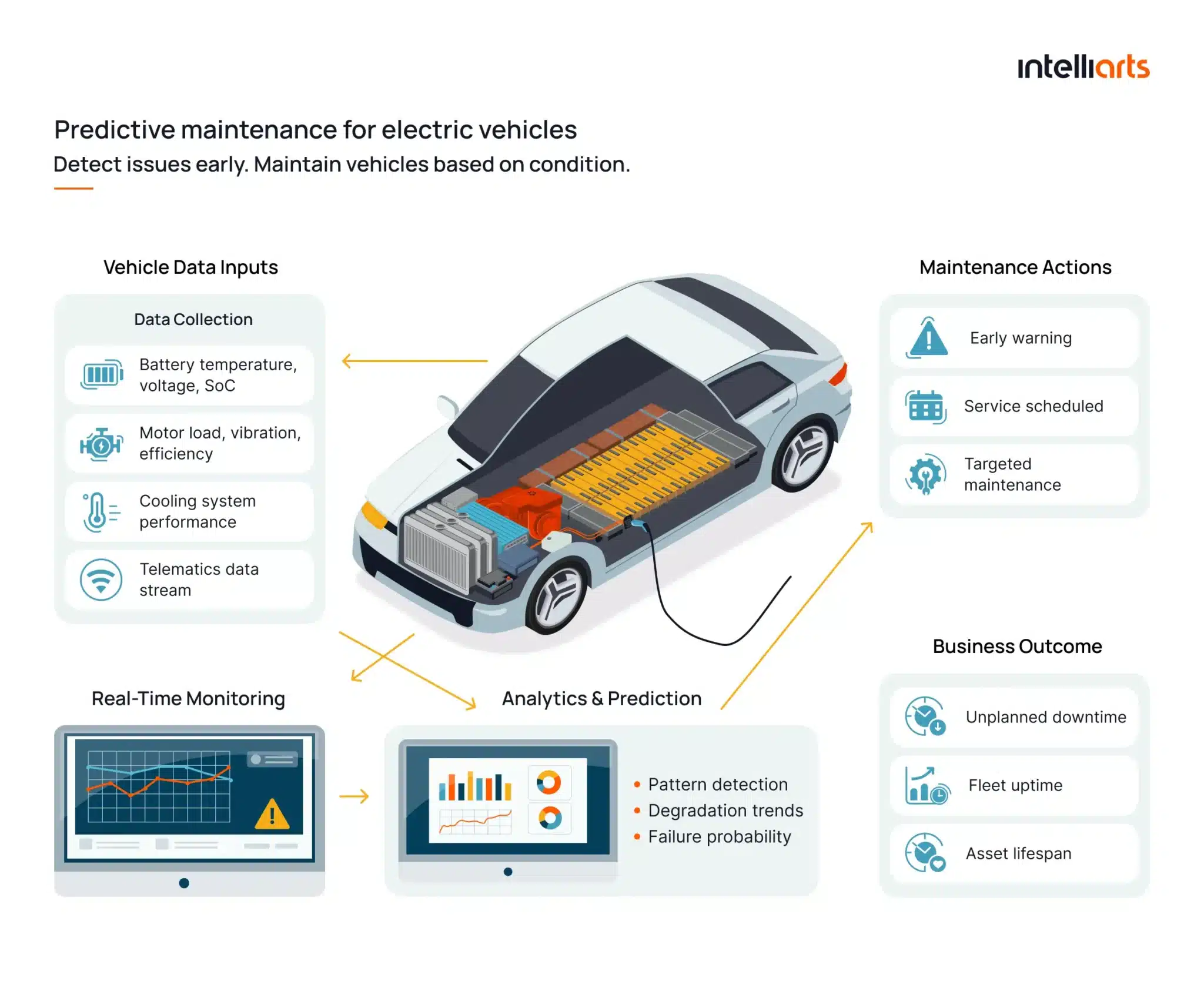

Hardware failures typically cost a pretty penny. What can be done about it? This issue can be addressed with something called predictive maintenance.

As opposed to reactive maintenance (in other words, fixing the machine that has already broken down), predictive maintenance will help you foresee that breakage and fix it before it even happens.

This approach relies on real-time data, sensors, and analytics to monitor equipment health and detect early signs of wear or malfunction. According to research data, predictive analytics and smart charging management systems can reduce operational costs by up to 35 %. By identifying anomalies before they escalate into failures, you can schedule maintenance at the right time, reduce unplanned downtime, extend hardware lifespan, and significantly cut repair and replacement costs.

- Software maintenance

While hardware reliability is critical, it’s only part of the equation. The software running EV chargers plays an equally important role in their performance, security, and long-term stability. To keep EV chargers operating reliably, they need regular over-the-air (OTA) updates that deliver the latest features, performance improvements, and security fixes. Delivering them consistently requires strong in-house expertise, which can take years to build. If developing this capability isn’t your current priority, collaborating with a proven technology partner can be a faster and safer path forward.

A practical example of this approach is our work with EVIQ, where Intelliarts delivered the core components of an EV charging management platform in just 6 months, well ahead of industry norms. The solution now supports tens of thousands of active users, maintains high platform stability through continuous updates, and has earned 4.1 rating on Android and 4.8 rating on iOS. By handling OTA updates, monitoring, and long-term software evolution, we help operators keep charging networks reliable without building large in-house teams from scratch.

Read the full case study about EVIQ software development.

3. Energy expenses

Electricity pricing is a major driver of operational costs. High utility rates, peak-time charges, and demand fees can significantly increase the cost of running a charging site, especially in regions where energy is already expensive. However, these expenses can be reduced with the right charging approach, making EV ownership more affordable. How, you may ask? With smart EV charging management, which helps optimize how and when energy is used.

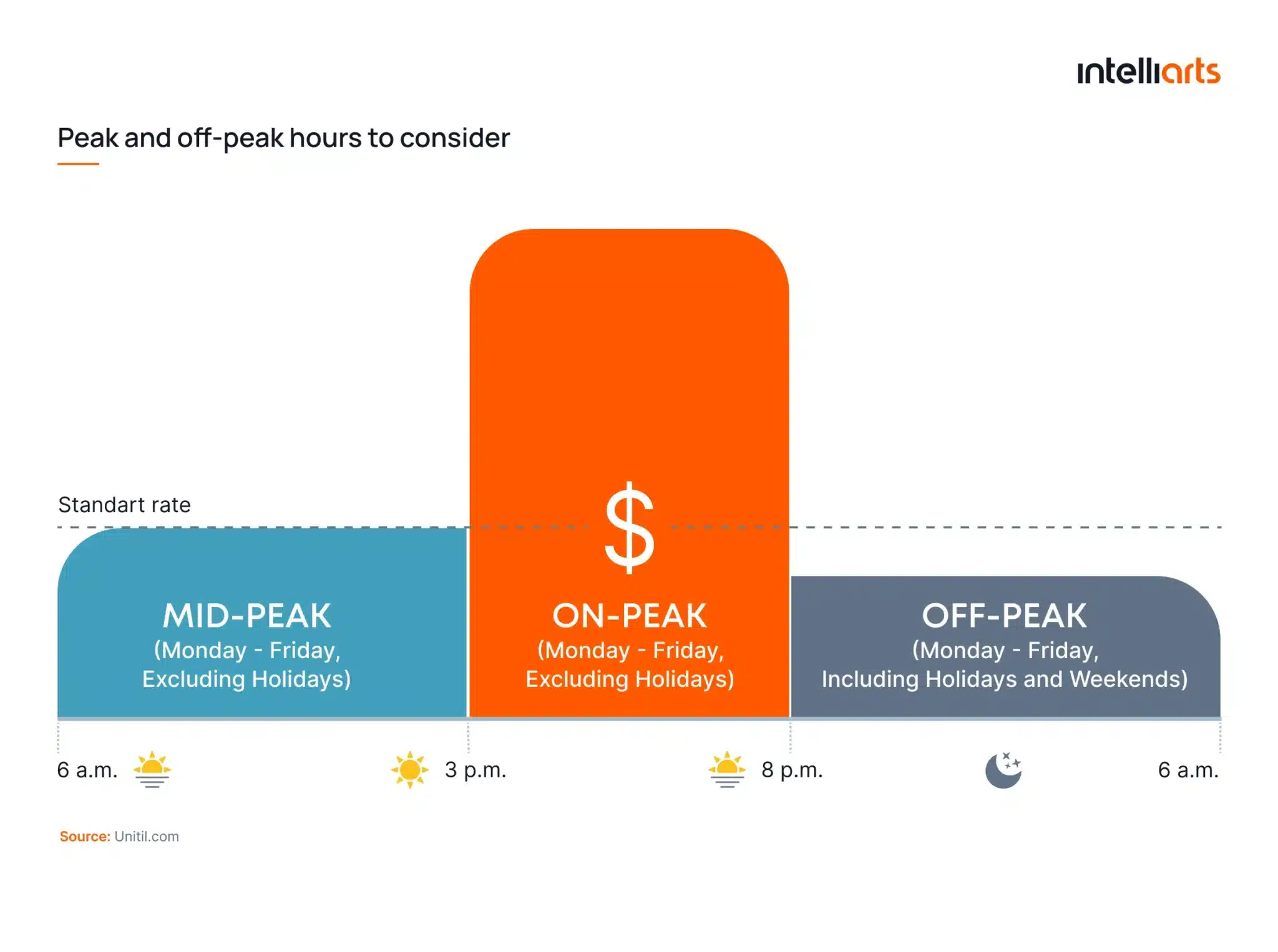

For instance, charging can be scheduled during off-peak hours, when electricity is cheaper. Load balancing can ensure power limits aren’t exceeded when multiple vehicles or devices draw power simultaneously. Access to chargers can be restricted to authorized users only, and continuous monitoring of the charging process helps maintain safety, performance, and a smooth user experience.

Approaches to reduce costs with smart EV charging management

Let’s now review additional ways to optimize costs with smart EV charging management, along with real-world case studies shared by Intelliarts experts.

1. Smart power management

Electricity costs fluctuate during the day: power is typically cheapest late at night and early in the morning. The logic behind it is lower demand means lower cost. So, utility providers have introduced time-of-use (TOU) pricing to encourage people to shift their energy consumption to periods of lower demand.

Smart power management leverages this pricing model by automatically scheduling charging sessions during off-peak hours, reducing electricity costs while easing strain on the grid. By aligning charging behavior with TOU tariffs, you can significantly lower energy expenses.

Case example: Power management software

Intelliarts experts have developed a power management solution for one of our clients. As a result, our client was able to achieve the following benefits:

The smart power management solution improved energy use, ensuring electricity was consumed at the right time and lowest cost. It helped charging operators avoid peak-demand spikes and gain better control over charging loads through a centralized platform and APIs.

By balancing power usage, site operators reduced electricity bills and avoided costly grid upgrades when adding more chargers. Better system monitoring extended infrastructure lifespan, reduced outages, and increased uptime. Built-in analytics gave operators clearer insight into energy usage, enabling smarter decisions. Overall, the solution supported more reliable service, lower costs, and improved sustainability.

2. Load balancing

Electricity costs often rise when multiple EVs charge simultaneously or when charging coincides with other energy-intensive equipment, such as HVAC (Heating, Ventilation, and Air Conditioning) systems or industrial machinery. These simultaneous loads can push total consumption beyond contracted limits, triggering demand charges and higher utility fees. Load balancing addresses this by actively managing power distribution across all connected devices.

In practice, load balancing sets a maximum power threshold for a site and continuously adjusts charging output to stay within that limit. For example, if four EVs are plugged in at once, the system can reduce charging power per vehicle instead of allowing a sudden spike in demand. When one vehicle finishes charging or other equipment powers down, the available energy is redistributed automatically, increasing charging speeds where possible.

Load balancing software makes this possible by monitoring energy usage in real time and dynamically controlling each charger. It coordinates EV charging with other electrical loads, prevents peak spikes, and keeps total consumption within allowed limits. As a result, businesses avoid costly demand charges, reduce the risk of overloads, and optimize energy use without investing in expensive grid or infrastructure upgrades.

Smart charging is about managing grid capacity and reducing peak load. It also helps to align charging behavior with real-time electricity pricing. By shifting charging to off-peak hours and dynamically balancing load, operators can meaningfully cut costs and reduce stress on the energy system.

– Ihor Rudnyk, eMobility Tech Specialist

3. Telematics for energy efficiency

Telematics plays a key role in improving charging efficiency by giving operators real-time visibility into how vehicles use power. Without this insight, EVs may charge more often than necessary, remain plugged in while fully charged, or follow inefficient routes that increase energy consumption and charging costs.

Telematics systems track battery state of charge, energy consumption patterns, driving behavior, and charging history. For example, operators can identify vehicles that consistently return with high battery levels and reduce unnecessary top-up charging, or spot inefficient driving and routing patterns that drain batteries faster than expected. Telematics data also supports smarter route planning, helping fleets complete trips with fewer charging sessions and lower overall energy demand.

Software makes this possible by continuously collecting and analyzing vehicle and charging data. AI-driven telematics platforms turn raw data into actionable insights, identify inefficiencies, recommend optimal charging and routing strategies, and support data-driven decisions that reduce energy waste, lower operating costs, and improve fleet performance.

Case example: Improving charging accuracy with telematics

Time for another case study, where telematics was one of the ways to address our client’s business pain. Our customer supports the setup, management, and optimization of EV charging stations. And they needed to improve their energy efficiency and charging accuracy.

To do so, Intelliarts introduced telematics that enabled wireless collection of vehicle data, providing fleet operators with real-time insights into energy consumption and charging needs, essential for reducing waste and controlling costs.

In this case, our experts integrated Geotab to collect data such as battery state of charge, energy consumption, and driving behavior. This enabled more accurate predictions of charging demand and better alignment between vehicle usage and charging schedules. Since the fleet also included electric buses, the team expanded the setup by integrating NFI Connect, a telematics platform for public transit, to monitor bus locations and charging operations.

By combining telematics data across different vehicle types, operators gained a unified view of fleet performance. This resulted in smarter charging decisions, fewer unnecessary charging sessions, lower energy costs, and improved operational efficiency across the entire fleet.

4. Predictive maintenance

Predictive maintenance is one of the most effective ways to reduce the day-to-day operating costs of EV chargers. Instead of fixing equipment only after it breaks, this approach focuses on spotting problems early and dealing with them before they turn into failures.

By continuously monitoring charger health like temperature, power fluctuations, error logs, or communication issues, operators can see when a component is starting to wear out or behave unusually. This makes it possible to plan maintenance in advance, at a convenient time, rather than reacting to sudden breakdowns that cause downtime and frustrate drivers.

From an operational perspective, the benefits are very tangible. Fewer unexpected failures mean fewer emergency repairs, less downtime, and longer equipment lifespan. Maintenance teams spend less time traveling to sites unnecessarily, and chargers stay available more consistently. Over time, this translates into lower maintenance costs, better reliability, and a more predictable operating model for EV charging networks.

Case example: Reducing downtime with predictive maintenance

One of our clients, EV Connect, has partnered with us to do just that. They needed to reduce charger downtime and improve infrastructure reliability through predictive maintenance. By analyzing historical charger data and identifying abnormal charging patterns, the team uncovered early indicators of potential failures.

This work enabled EV Connect to better understand real-world charger behavior, improve data readiness for machine learning, and prepare a scalable predictive maintenance system. As a result, the company gained stronger control over charger performance, lower maintenance risks, and a solid foundation for more cost-efficient operations.

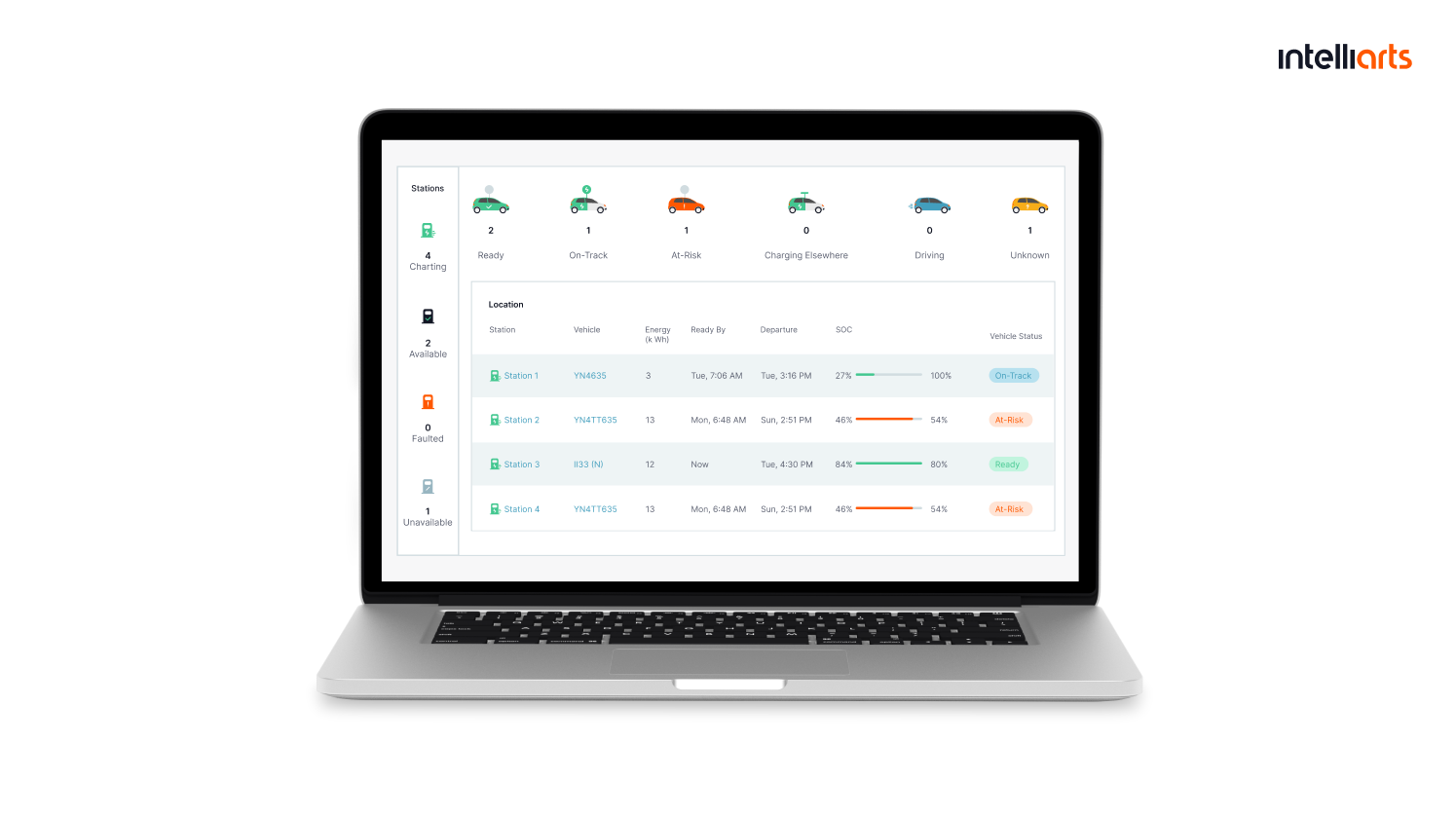

5. Remote monitoring and control

Managing charging stations on-site is time-consuming, costly, and difficult to scale. Remote monitoring solves this by giving operators real-time visibility into charger status, energy consumption, session activity, payments, and key performance indicators from a centralized dashboard.

With remote control capabilities, operators can detect issues such as offline chargers, failed sessions, or abnormal energy usage as soon as they occur and respond immediately. For example, many problems can be resolved remotely by restarting a charger, adjusting power limits, or updating configurations, eliminating the need for on-site maintenance visits.

As charging networks expand, implementing and maintaining smart charging capabilities becomes increasingly complex. Power management and all things software need to work together reliably and securely. For many businesses, this is where the right technology partner makes a real difference.

When choosing a vendor, it’s important to look beyond individual features and focus on long-term fit. A strong partner brings hands-on experience in EV charging software and infrastructure and understands the operational challenges of managing chargers at scale:

- Security should be built in from the start, with proven practices such as secure authentication and encryption to protect remote updates and sensitive data.

- Just as important is compatibility: the solution should support multiple charger models and communication protocols, allowing your network to grow without being locked into a single vendor.

- Seamless integration with your existing charging management system is also key, as it reduces manual work and keeps day-to-day operations efficient.

Wrap-up

As EV adoption continues to grow, efficiently operating the charging infrastructure becomes just as important as expanding it. Energy costs, maintenance, and infrastructure constraints can quickly add up, making cost optimization an essential part of running a sustainable charging network.

Smart EV charging management brings predictability to these challenges. Using technology, operators can better align charging with real demand, reduce unnecessary energy costs, and maintain reliable operations as networks scale.

The Intelliarts case studies show how these approaches translate into measurable results: lower operating costs, improved uptime, and greater visibility across charging operations. For businesses investing in EV charging, a strong technology partnership can provide a solid foundation for long-term efficiency and growth.

Ready to optimize your EV charging operations and reduce costs? Contact us to learn how our solutions can help your business save and scale.